NBM Series

Electronic Zero Loss Drain

NEXT’s NBM Series electronic zero loss condensate drains are designed for efficient removal of unwanted condensate particulates, or other moisture within the air stream. Zero loss drains operate by only releasing condensate when there is condensate present within the reservoir. Through this process the Zero loss drain does not allow any compressed air to escape from the system, which results in the saving of compressed air. Controlled by a state-of-the-art processor, the NBM prevents blockages with a specially engineered series of integrated valves that adjust automatically when condensate is detected at the maximum level. Available in a wide spectrum of models, the Aqua Pure NBM drain utilizes precision engineering and design to enhance condensate management by eliminating drain maintenance and compressed air loss.

NBM Series Features

- Sensor-Controlled True Zero loss

- Integrated Alarm

- Visual Status LED Indicator Lights

- UL & CSA Certified

- Integrated Sieve –Eliminates Need for Y Strainers

- Engineered for Low Maintenance

- Manufactured with Corrosion Resistant Materials

Benefits

- Prevention of Unnecessary Compressed Air Losses

- Reduction of Energy Costs

- Condensate Discharge Depending on the Accumulated Condensate Amount

- Safe Discharge, in case of Strong Contamination

- Low Noise Deployment During Draining Process

- Aids to Save Time and Capital

- Ease of Maintenance is Designed for Quick and Hassle-free Service

True Zero Air Loss

- Operating Principle guarantees maximum energy savings

Highest Reliability

- Integrated sieve eliminates any concern about dirt, the need for a Y strainer, and extra maintenance

Lowest Maintenance

- Reduce overall time and costs and make maintenance fast and easy

Sensor Controlled

- Ensures intelligent operation at all times with the ability to automatically clear clogs and debris

Integrated Alarm

- Visual status indication is given on the drain and can be wired for remote access

Fully Automatic

- Continuously monitors both level and function for autonomous operation

Lowest Maintenance

Min /Max Operating Pressure

- 12 to232 psig

- .8 to 16 bar

Min / Max Operating Temperature

- 33 / 140 ° F

- .5 to 60 ° C

Compressor Flow Rate

- 100 to 50,000 CFM

Diaphragm Material

- Viton

Standard Voltage

- NBM-31-33: 95-240 VAC 50/60 Hz

- NBM-13-16: 115 VAC

Optional Voltage

NBM-31-33:

- 18-72 VDC

- 24-48 VAC

NBM-13-16:

- 24 VAC/DC

- 48 VAC

- 230 VAC 50/60 Hz

Certifications

- UL /CUL/ CSA

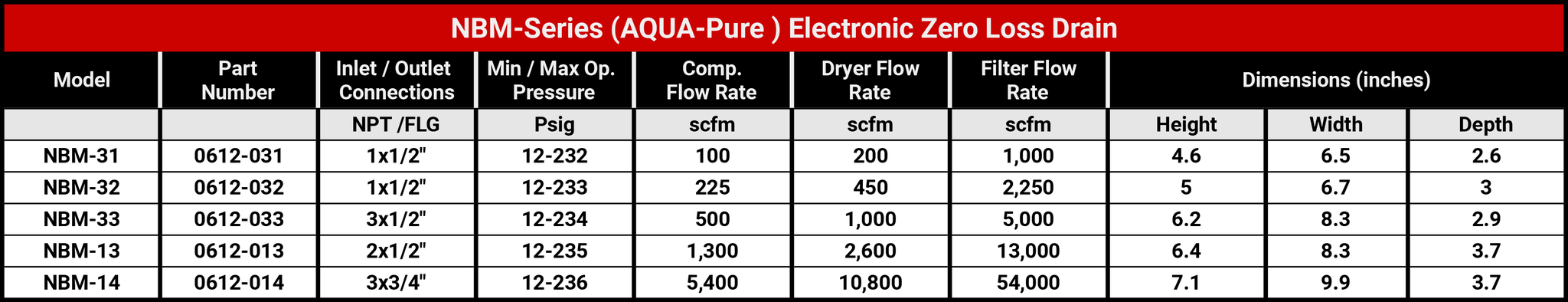

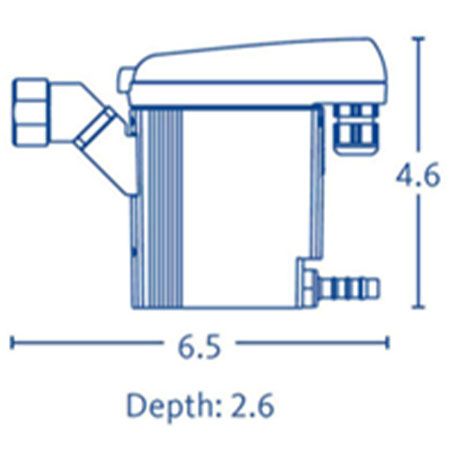

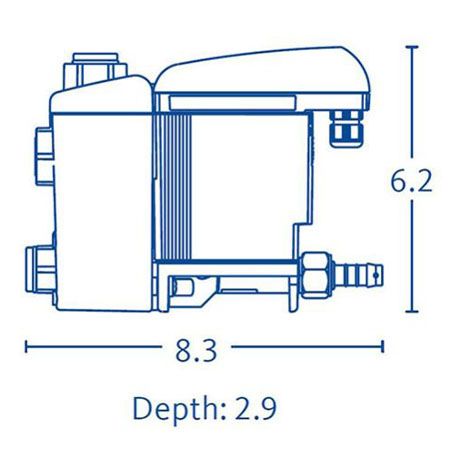

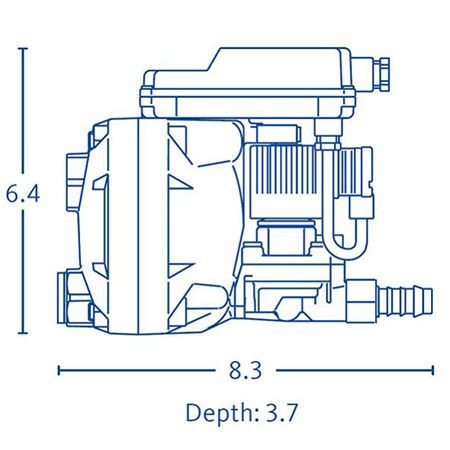

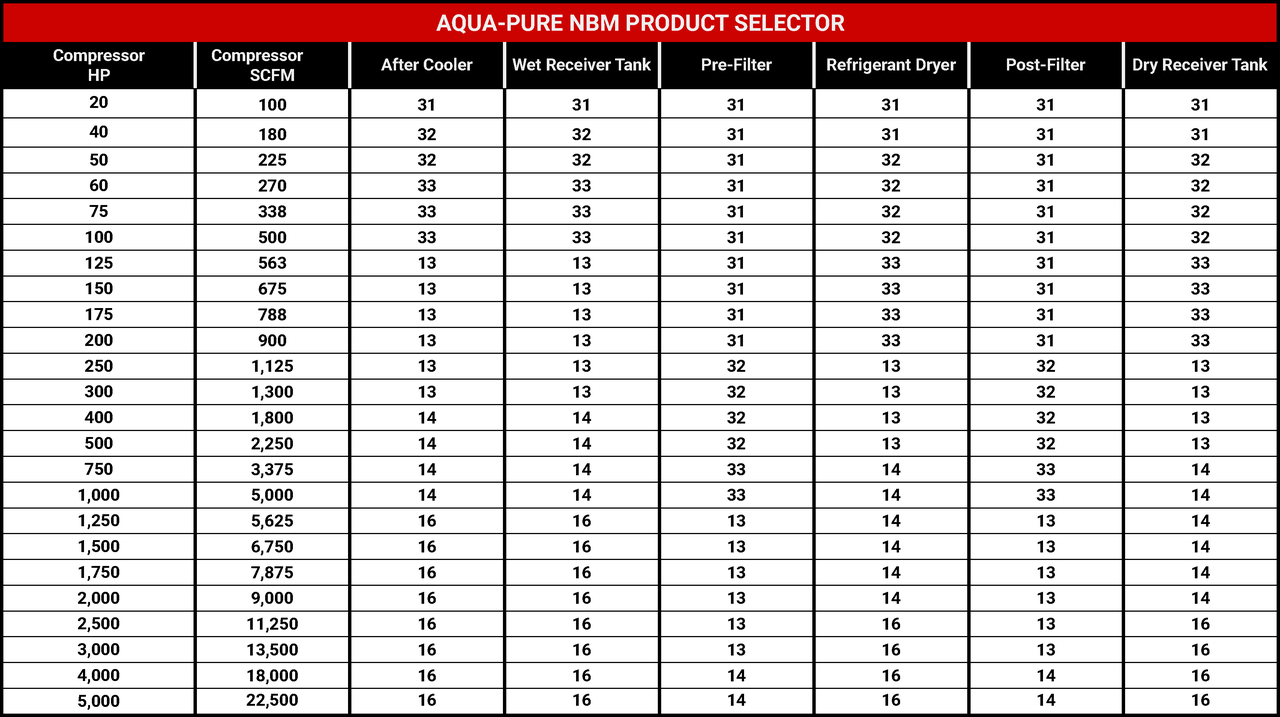

NBM Series Models

Product Selector

NBM Series Options

Alternate Voltages:

NBM-31-33

- 18-72 VDC

- 24-48 VAC

NBM-13-16

- 24 VAC/DC

- 48 VAC

- 230 VAC 50/60 Hz

Additional Options

- Drain Heater

- Insulation Sleeve/Shell

Your next step toward working with NEXT Air & Gas is to contact us for a Quote. Fill out the information below and give us the appropriate information needed to get started. Be sure to fill out all the contact information and our team will reach out with any questions or concerns.

If you’d rather speak to Sales Engineering, feel free to contact us at (865) 635-8178.

Below are links to product information and brochures. Please click and download at your convenience. If you have any questions or suggestions on materials you think would be helpful, please call us at (865) 635-8178.

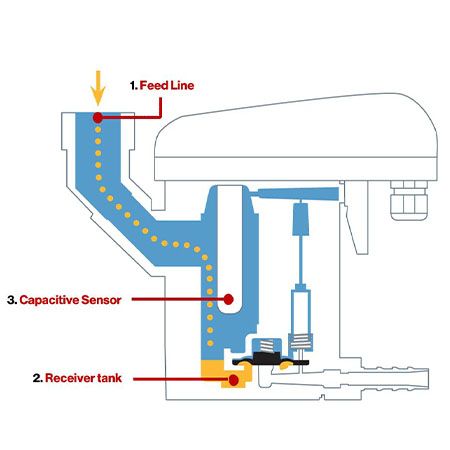

Principles of Operation

NEXT’s NBM Series electronic zero loss condensate drains are designed for efficient removal of unwanted condensate particulates, or other moisture within the air stream. Zero loss drains operate by only releasing condensate when there is condensate present within the reservoir. Through this process the Zero loss drain does not allow any compressed air to escape from the system, which results in the saving of compressed air.

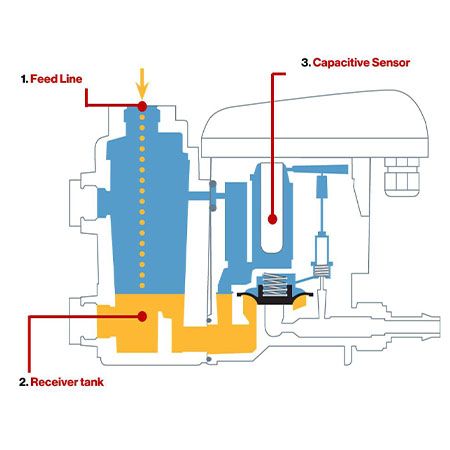

Empty: The Condensate flows into the NBM via the feed line (1) and accumulates in the receiver tank (2.) A capacity functioning sensor (3) continuously records the filling level and sends a signal to the electronic control as soon as the container is filled.

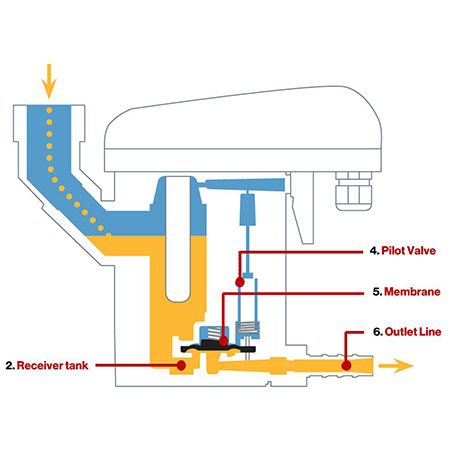

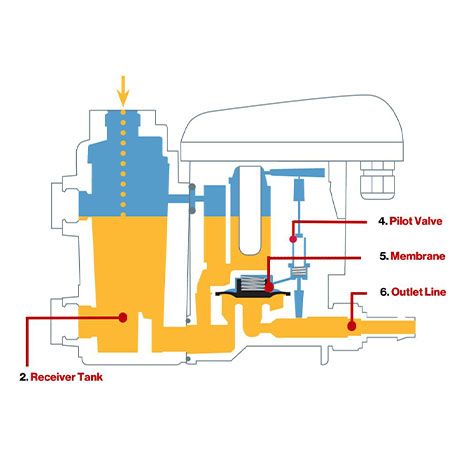

Filled: The pilot valve (4) is activated and the membrane (5) opens the outlet line (6) for the discharge of the condensate. When the NBM is empty, the outlet line is tightly reclosed in time before any unnecessary compressed air losses can occur.

Overview

Next Air & Gas Performance Advantages

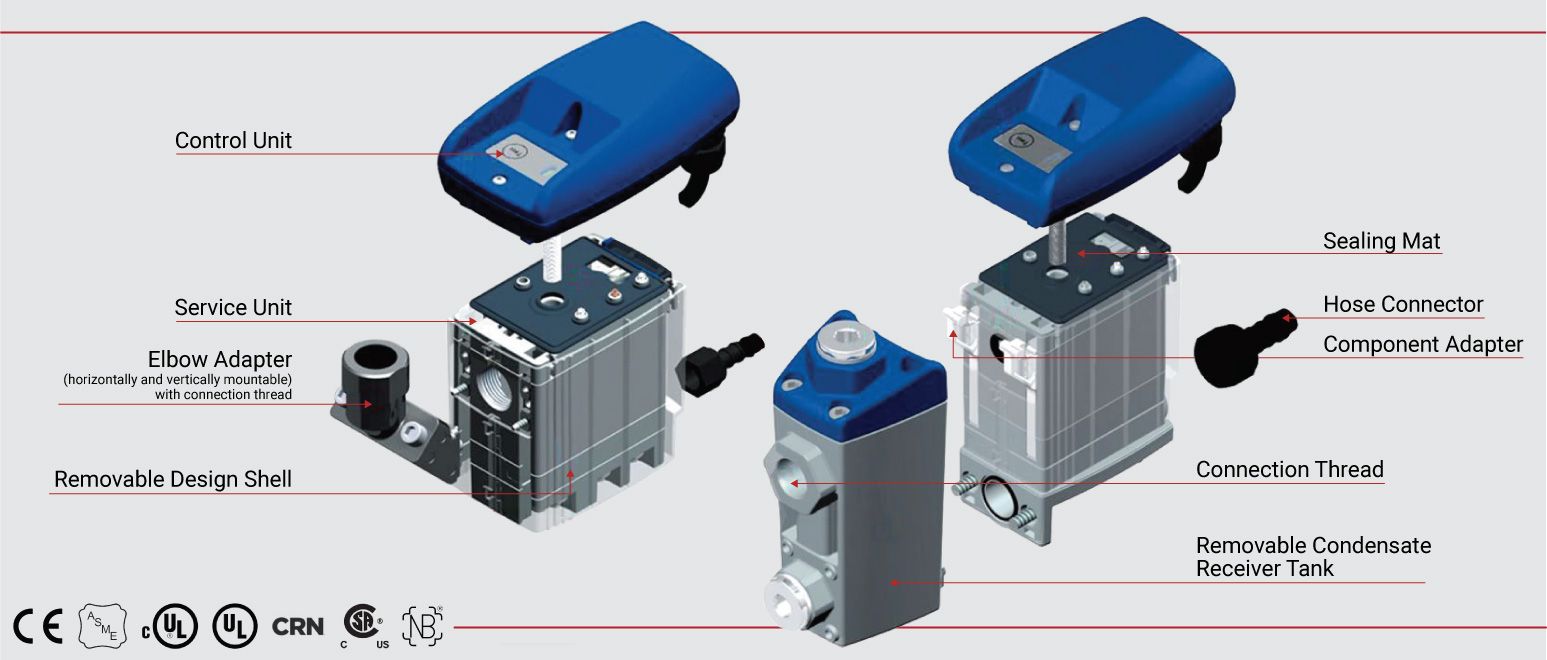

The innovative design enables simplified handling as well as installation and maintenance with minimum time expenditure. The devices consist of no more than three units joined together with quick-release connectors. The control and sensor units are only installed once, only the service unit (including all wear and pressure parts) needs to be exchanged for maintenance purposes. This robust condensate drains are suitable for both oil-contaminated and oil-free, aggressive condensates.

Easy Maintenance

Maintenance time and costs are kept to an absolute minimum with a quick and easy procedure consisting of just one part.

Robust & Reliable

The NBM design is made in corrosion resistant aluminum, which makes the NBM series particularly reliable and robust. A silver coating protects the outside of the housing.

Energy Savings

Maximum energy savings is achieved from efficient design, operation that guarantees true zero air loss.

Reliability

An integrated sieve eliminates concerns about dirt, Y Strainers, and extra maintenance giving you the highest level of reliability.