NXP Series (75-10,000 ACFM)

Oil Water Separator

Next’s NXP Series Oil & Water Separators are designed to separate compressor oil from condensate with high efficiency without the use of external power. The NXP oil water separators use a propriety alumina silicate substrate media bed to adsorb all compressor- based lubricants, including silicone, polyalkylene glycol (PAGs), and food grade. The innovative NXP is maintenance-free and mold resistant design also makes it EPA compliant.

NXP oil-water separators play a crucial role in maintaining operational efficiency, protecting equipment, and minimizing environmental impact in compressor rooms and other industrial settings where oil-contaminated water is generated. By effectively separating oil from water, the NXP separators contribute to sustainable practices and ensure compliance with environmental regulations. Whether you’re running 15HP or 600HP, there’s a NXP oil water separator to match your medium to large, compressed air system.

NXP Series Features

- Best value oil water separator in the market

- Efficiently & effectively removes all oils, including glycol- base lubricants

- No maintenance

- No messy bag change-outs

- Cradle to grave warranty

- System monitoring services (500-1500)

- Compression-fit manifold for precise filtration control

- Timer drains for improved flow of condensate through the media bed (500-1500)

- Antimicrobial sanitation of discharge hose to prevent algae growth

- Up to twelve available inlets

- Alarm management

- Gravity flow discharge

- 10 ppm or less carryover thought the life of the unit (lowest in the industry)

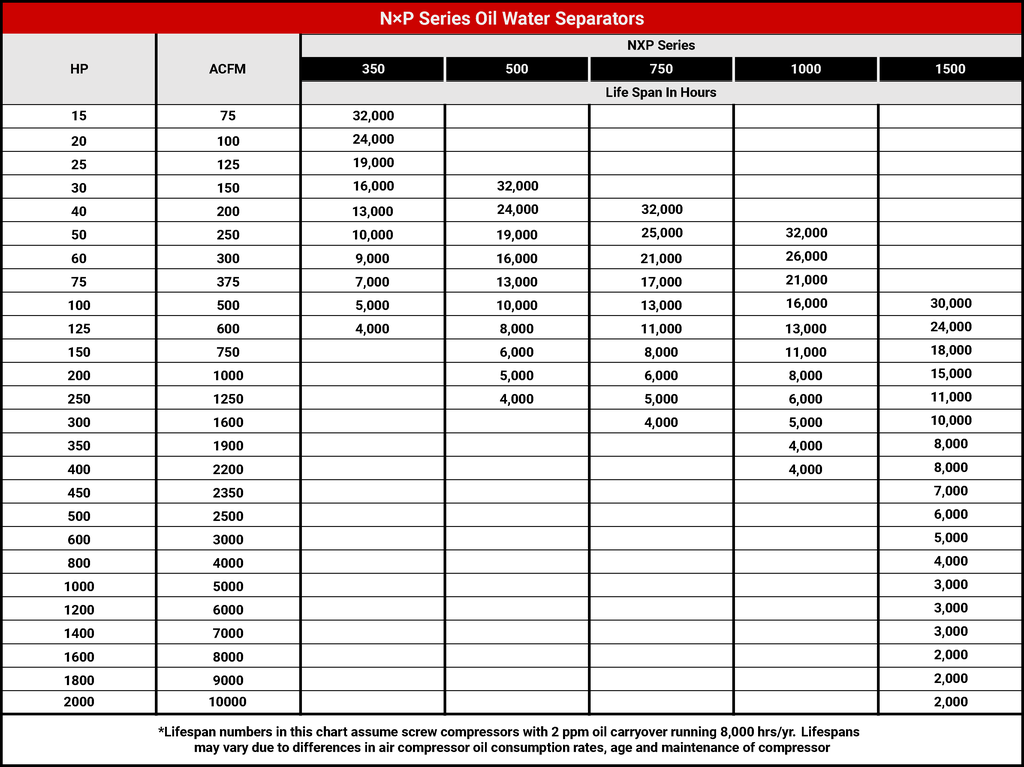

Compressor Horsepower Capacity

- NXP-350 (30 to 250 HP)

- NXP-500 (30 to 250 HP

- NXP-750 (40 to 300 HP)

- NXP-1000 (50 to 400 HP)

- NXP-1500 (125 to 600 HP)

- NXP-2000 (800 to 2000)- Contact factory

Maximum Compressor Capacity

- 20 to 3000 scfm

Minimum Working Air Temperature

- 33°F (1°C)

Maximum Working Air Temperature

- 155°F (68°C)

Connection Port Size

- ¼” & ½”

COMPRESSOR LUBRICANT COMPATIBILITY

- Diester-based

- PAO-based

- POE-based

- Glycol-based

- Hydraulic

- Food Grade

- Mineral-based

- Anderol

- Ultra Chem

- Summit

- Gardner Denver

- Kaeser

- Quincy

- Atlas Copco

- Palatek

- Compare

- Ingersoll-Rand

- Sullair

NXP Series

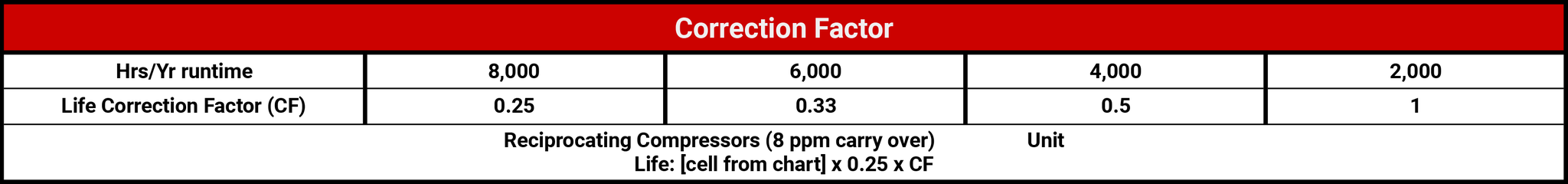

Correction Factors

Your next step toward working with NEXT Air & Gas is to contact us for a Quote. Fill out the information below and give us the appropriate information needed to get started. Be sure to fill out all the contact information and our team will reach out with any questions or concerns.

If you’d rather speak to Sales Engineering, feel free to contact us at (865) 635-8178.

Below are links to product information and brochures. Please click and download at your convenience. If you have any questions or suggestions on materials you think would be helpful, please call us at (865) 635-8178.

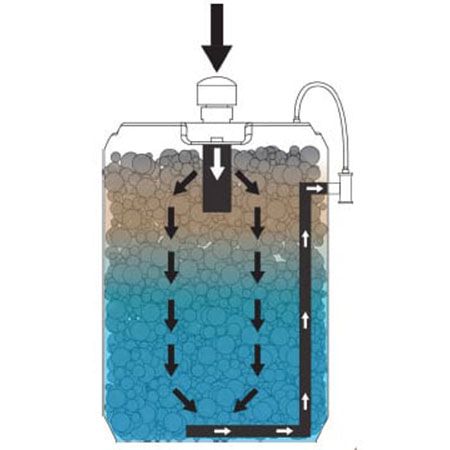

Principle of Operation

Media Utilizes molecular Sieve technology and chemical bonding. Lubricant molecules attract to the substrate media bed like a magnet, permanently bonding and eliminating groundwater contamination

The operation of an oil-water separator typically involves several stages:

- Coalescence: The mixture of oil and water enters the separator, where it encounters a series of baffles or plates. These elements slow down the flow and allow oil droplets to coalesce, forming larger droplets.

- Separation: The larger oil droplets rise to the surface due to their lower density, forming a layer of oil on top of the water. This oil layer is then skimmed off and collected for proper disposal or recycling.

- Filtration: To further enhance the separation process, some oil-water separators incorporate filters or media that help trap and remove any remaining oil particles or contaminants.

- Water discharge: The separated water, which is now relatively free of oil, exits the separator through an outlet and can be discharged or further treated, depending on local regulations.

Overview

NXP-350

- Condensate Inlet Hub

- Vent

- Outlet drainage Line

- Anti Siphon Line

- Condensate Inlet Connection

- Exhaust Vent

- Outlet T Drainage Line

8. Condensate Manifold

9. Condensate Inlet Connection

10. Exhaust Vent

11. Timer Drain

12. Antimicrobial Cavity

13. Outlet

Next Air & Gas Performance Advantages

Maintenance-free-technician approved

- No heavy, messy bag change outs

- No exposure to algae, black mold, bacteria or e-coli

- Reduces or eliminates illness and allergic reactions

Recycle Program

- Dispose of in accordance with state and local regulations or,

- Ship registered NXP to Next for free recycling

Environmental conditions

- Works in all condition- contact Next for extremely cold climates

- Specific gravity, emulsifications, relative humidity and temperature do not affect performance.

CLASS SEPARATION

- CLASS 1. (HIGH SEPARATION EFFICIENCY)

- Additive free turbine oil

- CLASS 2. (MEDIUM SEPARATION EFFICIENCY)

- Mineral, Polyalphaolefins (PAO)

- Trimethylolpropane Ester (TMP)

- Pentaerythritol Ester (PE)

- CLASS 3. (LOW SEPARATION EFFICIENCY)

- Diesters

- Triesters

- Polyoxyalkylene glycol (PAG)