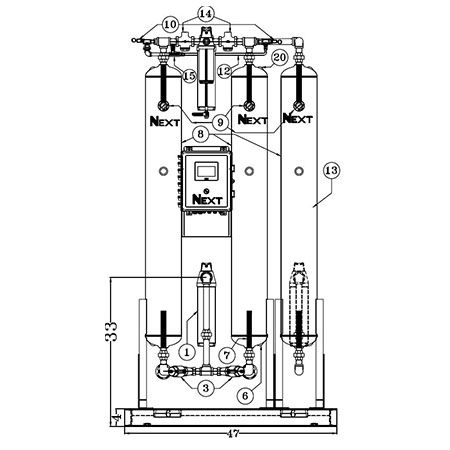

BHL Series (45-1000 CFM)

Breathing Air Regenerative Dryers

The Breathing Air Series is a fully automatic purification system that uses twin tower regeneration technology to purify compressed air into breathing air by removing a variety of harmful contaminants such as moisture, solid particles, oil or oil vapors, carbon monoxide and hydrocarbons. These contaminants adversely affect workers’ health and safety and reduce productivity. Respiratory ailments frequently cause absenteeism.

The BHL series are designed to meet OSHA standards with the inlet carbon monoxide concentration of up to 400 PPM at the purifier inline. Next’s breathing air series meet stricter CSA standards for inlet carbon monoxide concentration up to 100 PPM.

For higher levels of contaminant at intake, consult the factory. The BHL Series has robust valving and includes high quality coalescing pre-filter, activated carbon after-filter, and a particulate final-filter mounted as a standard feature.

The BHL Series achieves efficiency with its multi-stage purification and dehydration process without the addition of multi vessel switching that is utilized by competitors.

The series also pays off many times over, not only in safety and their productivity, but because of their low operating costs.

BHL Series Features

- Mounted Filtration

- Control Line Filter

- Pre filter

- 2nd pre filter

- After filter

- NHDC-2300, 4.6 HMI -Touch Screen Controller

- UL, CUL, Electrical Certifications

- ASME, CRN Code Welded Pressure Vessel Certification

- Stainless Steel Angle Body Valves / Butterfly Valves

- Tower Pressure Relief Valves

- Purge Adjustment Valve

- Purge Flow indicator

- Horizontal Purge exhaust mufflers

- Tower Pressure Gauges

- Stainless steel Desiccant Strainers

- Counter-Current Re-pressurization

- Nema-12 Electrical enclosure

- Field adjustable Drying Cycle time (6,10,15 min)

- Separate Drain and Fill port

- Fail-Safe Design

- Common Alarm Output

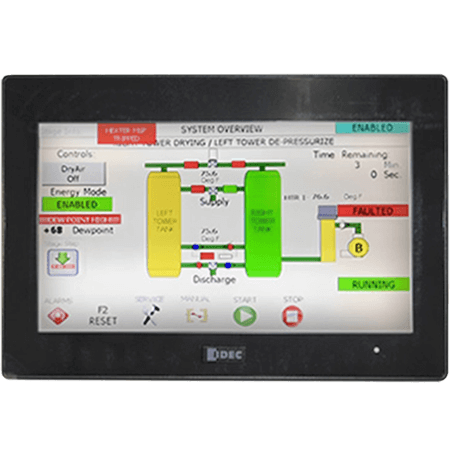

NHDC-2300 Controller

- 4.6 Color touch screen HMI interface

- Energy management system

- Main display shows the following information

- Dewpoint

- Drying, Regenerating, and Repressurizing Side

- Time Remaining for each state

- Outputs 10+

- Digital Dewpoint Trend

- Alarm status

Operating Voltage

- 110, 115 V / 1 PH / 50-60 HZ

- 230/208/220 V / 1 PH / 50-60 HZ –(Optional)

- 24 V DC- (Optional)

Pressure Vessel Certification

- ASME VIII, CRN

Control Panel Certification

- UL & CUL

- CSA– (Optional)

Pre & Post Filtration Microns

- Pre-Filtration grade 0.01 μm

- Post-Filtration grade 1 μm

- Secondary Carbon Filter (Optional)

Electrical Enclosure Rating

- NEMA 12

Average Purge Air*

- 15%

Outlet Pressure Dew Point

- -40° F / ° C

- -100 ° F / -73° C (Optional)

Min/Max inlet air temperature ° F / ° C

- 40/120 ° F

- 4.4/48 ° C

Min/Max Operating Pressure

- 60/150 Psig

- 4 / 10 Bar

Design Pressure

- 200 Psig

- 13.7 Bar

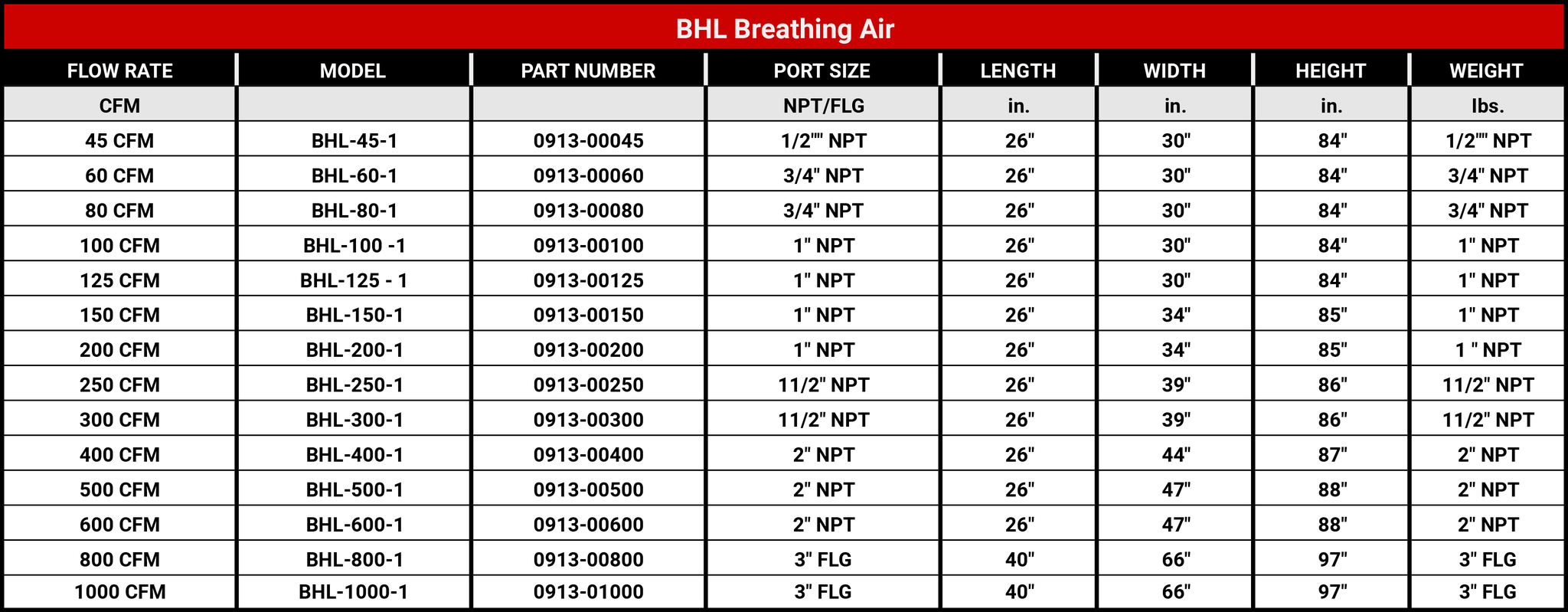

BHL Series Models

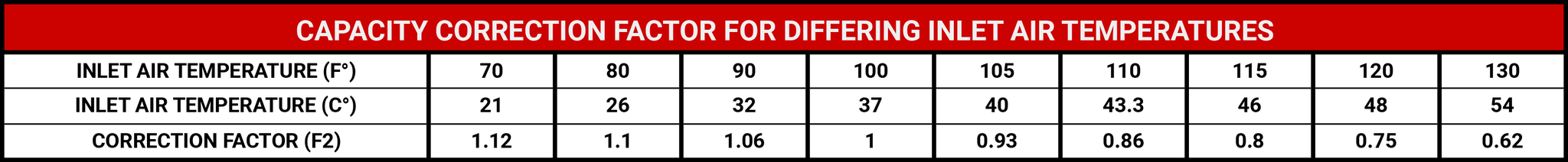

Correction Factors

*Additional Flows Available Upon Request

Correction Factors

Air Flow Capacity = Operating Pressure x Inlet Air Temperature

Additional Flows available on request.

Correction Sample:

If a compressor delivers 500 scfm at 120 psi pressure with a 120°F inlet temperature, please choose your dryer model as follows:

(500 scfm / 1.08 / .75) =617 scfm, therefore an BHL-600 would be needed.

(If an option is not listed, please contact our sales team to accommodate any additional options.)

ALTERNATE VOLTAGES:

- ALT-V-1: 208-230 VOLTS / 1 PHASE / 50-60 HZ

- ALT-V-2: 24 VOLT DC

- ALT-V-3: 12 VOLT DC

- PC: PNEUMATIC CONTROL

ELECTRICAL ENCLOSURE:

- N4: NEMA 4: ELECTRICAL ENCLOSURE

- N4X-P: NEAMA 4X: POLYCARBONATE ELECTRICAL ENCLOSURE

- N4X: NEMA 4X: STAINLESS STEEL ELECTRICAL ENCLOSURE

- N7: NEMA 7 EXPLOSION PROOF

CONTROLLER:

- ALT-C-1 NHDC-2300:

- ALT-C-3 NHABC:(ALLEN BRADLEY INTERFACE)

- ALT-C-4 NHSC:(SIEMENS INTERFACE)

CONDENSATE DRAIN:

- EFD:EXTERNAL FLOAT DRAIN

- EZLD:ELECTRONIC ZERO LOSS DRAIN

- PZLD:PNEUMATIC ZERO LOSS DRAIN

- HPTD:HIGH PRESSURE TIMER DRAIN

DEW POINT & DIGITAL MONITORING:

- DCC+DDP: DEMAND CYCLE CONTROL

- DDPM-40: DIGITAL DEW POINT MONITOR (-40° F/ -73° c)

- DDp-40: DIGITAL DEW POINT sENSOR (-40° F/°C)

- DDP-100: DIGITAL DEW POINT sENSOR (-100° F/ -73° c)

- FTS: FAILURE TO SWITCH ALARM

- DCA: DRY CONTACT ALARM

- ESS: EMERGENCY STOP SWITCH

- RSS: REMOTE START / STOP

- dos: Digitail oxygen Sensor

BYPASS:

- 3VBP: THREE VALVE BYPASS

- 9VBP:NINE VALVE BYPASS

FILTRATION:

- DPFDUAL PRE FILTER

- daf: dUAL aFTER fILTER

- SP-F:SPECIAL FILTER CONFIGURATION

- FS: FILTER SKID

- RSS: REMOTE START / STOP

PACKAGES:

- LAP:LOW AMBIENT PACKAGE

- SZ:SUBZERO PACKAGE

- RS: RENTAL SKID

CONSTRUCTION:

- NYM:NO YELLOW METAL

- SP-DIM:SPECIAL – DIMENSION

- CSA:CANADIAN STANDARDS ASSOCIATION

- CRN: CANADIAN REGISTRATION NUMBER (3000+ CFM)

- BTS:BUILT TO SUIT

- IOPG:INLET-OUTLET PRESSURE GAUGE

- IOTG:INLET-OUTLET TEMPERATURE GAUGE

- TTG:TANK MOUNTED TEMPERATURE GAUGE

- VMI:VISUAL MOISTURE INDICATOR

- SST:STAINLESS STEEL CONTROL AIR TUBING

- CR:CONTROL LINE PRESSURE REGULATOR

- EPH:ELECTRICAL PANEL HEATER

- AC: AFTERCOOLER

- TAG: STANDARD STAINLESS STEEL IDTAGS

- MGP: MARINE GRADE 2 PART EPOXY PRIMER & PAINT

- RV: RECEIVER VESSEL

Your next step toward working with NEXT Air & Gas is to contact us for a Quote. Fill out the information below and give us the appropriate information needed to get started. Be sure to fill out all the contact information and our team will reach out with any questions or concerns.

If you’d rather speak to Sales Engineering, feel free to contact us at (865) 635-8178.

Below are links to product information and brochures. Please click and download at your convenience. If you have any questions or suggestions on materials you think would be helpful, please call us at (865) 635-8178.

Principles of Operation

- Stage 1: Inlet Particulate & Coalescing Pre-Filter The pre-filter removes particulates, water aerosols, and oil mist content efficiently. The pre-filter is equipped with a differential pressure indicator and a zero-loss automatic condensate drain valve.

- Stage 2: 13X Molecular Sieve The inlet portion first layer of the adsorbent media filled in the towers is 13X molecular sieve to remove contaminants such as volatile organic compounds, acid forming gases, base gases and moisture. •

- Stage 3: Activated Alumina This layer of activated alumina removes moisture to a dewpoint of -40°F and below line pressure. •

- Stage 4: Carulite Catalyst The catalyst layer is used to convert carbon monoxide to carbon dioxide and to oxidize residual hydrocarbon vapors.

- Stage 5: Activated Alumina This final layer of activated alumina is installed at the top of the towers to remove residual contaminants.

- Steps 2-5: The towers absorb and regenerate alternatively. The regeneration of this unique multi-layer adsorbent media and catalyst arrangement typically extends its life under normal conditions to three years. The control system sequence is monitored by a standard fail to switch system using pressure transducers and alarms when the system does not function properly.

- Stage 6: Activated Carbon After-Filter The activated carbon contained in the filter element assures a residual oil vapor content below 0.003 ppm. The filter is equipped with a manual ball valve.

- Stage 7: Sub-Micron Final-Filter The final-filter efficiently removes fine aerosols and particulates generated in the system. The filter is equipped with a differential pressure indicator and manual ball valve. • The outlet air is monitored by a high-quality Carbon Monoxide (CO) analyzer and triggers an alarm when a preset level is reached.

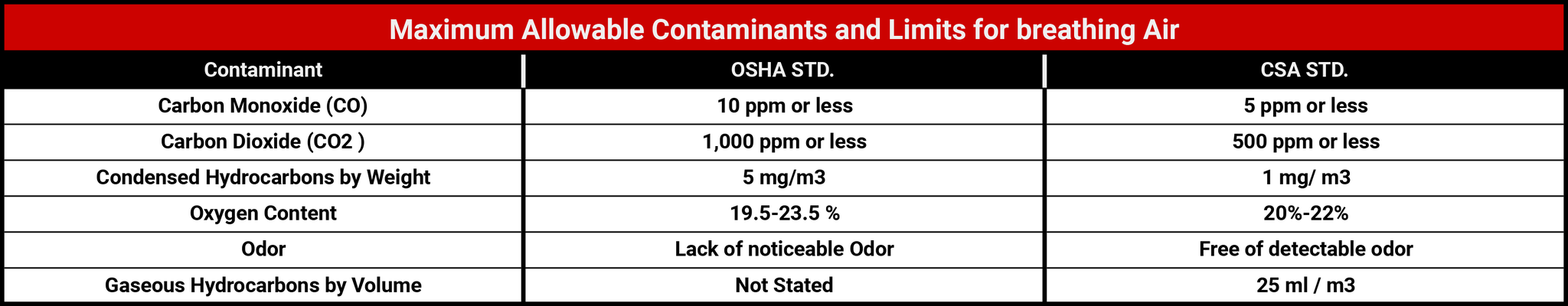

BHL Series Outlet Air Quality

Maximum Allowable Contaminants and Limits for Breathing Air

NOTES:

- According To: OHSA GRADE D (UNITED STATES) & CSA Z180.1-13 (CANADA)

- Removes only hydrocarbons adsorbed by activated carbon (does not remove methane)

- The system does not add or reduce oxygen levels. Inlet air must have adequate oxygen content.

- Removes only odors adsorbed by activated carbon

The BHL Series are designed to meet OSHA Standards with the inlet carbon monoxide concentration of up to 400 ppm at the purifier inlet. The BHL meets stricter CSA Standards for inlet carbon monoxide concentration up to 100 ppm. For Higher levels of contaminants at intake, please consult with factory.

Next Air & Gas Performance Advantages

The performance of any desiccant dryer depends on the quality of its key components. Next Air & Gas uses the best available valves, controllers and desiccant. With accurately designed and sized components, the dryers are manufactured to provide you with years of trouble-free operation.

State of the Art PLC with Touch Screen Interface

The entire drying/ regeneration cycle is controlled by a Micro-Logix programmable logic controller (PLC), among the most reliable controllers available. The plc is supplied with a 4.6″ touch screen HMI display which, among other items, will provide the operator with the following information.

- 4.6 Color Touchscreen HMI Interface

- Energy Management System

- Main Display Provides Multiple “at a glance” Data Points:

- Dew Point -OP+

- Drying, Regenerating, and Repressurizing Side

- Time Remaining for Each State

- Alarm Status

- Process History

- % Energy Savings

- Filter Maintenance Indicator

- Modbus TCP Communication

- Remote Start Stop

- Outputs 10+

- Digital Dew Point Control Dew Point Trend

Pressure Vessels

BHL desiccant vessels have been designed with a wide diameter for a large cross- sectional flow area. This results in a low flow velocity which minimizes both pressures drop across the bed and attrition of the desiccant itself. The Vessels incorporate the flowing additional features:

- Stainless steel inlet and outlet air diffusers for even flow distribution

- Stainless steel bed support on units above 3,000 scfm

- Desiccant fill and drain ports

- 1/16” corrosion allowance

- Operating pressure gauge on each vessel

- Pressure relief Valve on each vessel

- ASME / CRN Certified

Digital Dewpoint Transmitters Optimize Operations

NEXT’s FAN-500 and 510 are the ideal dew point sensors for monitoring dew point changes for our desiccant dryers. If your needs include a set dew point of -40° F or -100° F, NEXT’s range of dew point sensors has it covered.

- Modbus-RTU Interface

- Higher Resolution of Sensor Signal Through Improved Evaluation Electronics

- Integrated Display (Fan-500)

- Pressure-tight up to 5,000 psig./350 Bar (special version)

- Extreme Long-Term Stability

- Quick Response Time

Quality Desiccant Media

Next Air & Gas uses a mixture of adsorption media in its heatless range of desiccant dryers to achieve consistent dewpoint. Activated Alumina, Molecular Sieve and Silica Gel are used in varying ratios depending on the application. The long lasting, high crush strength media has a very high surface/volume ratio. Beaded activated alumina is used as the adsorption media in heated desiccant dryers. The beads exhibit a very high internal surface area and high moisture separation efficiency. Each lot of desiccants is thoroughly tested for density, moisture content, abrasion resistance, surface area, mesh size and granule strength to assure that it meets strict design requirements.

Butterfly Valves for Precise Control

These versatile, high-performance butterfly valves are used by Next Air & Gas to provide you with precision control and complete bubble-tight shut off. The digitally controlled actuators provide an easy PLC interface and feature fast response time. The tongue-and-groove seat design feature ensures complete isolation of flowing media from the body and stem. Rugged and reliable, these valves are designed to provide years of trouble-free service.

Angle Body Piston Valve

These high-performance, 2-way direct acting valves are designed for reliability and durability. They utilize a profiled disc in conjunction with a high-resolution compact positioner and linear feedback potentiometer to provide precise proportional flow. The stainless-steel internals and a tough fiber composite actuator body, along with the use of oversized bearing and Viton® seals, make it possible to consistently provide smooth piston movement for years of trouble-free service. Angle body valves are used to control depressurization of the regenerating vessel and to control the dry purge air flow during the cooling phase of the process. Angle body valves offer high flow rates and long service life in compact, economical packages.

Carbon Monoxide Monitor

The unit delivers specific and accurate measurement of carbon monoxide, oxygen or dew-point levels are required. Designed to meet OSHA requirements for monitoring of Grade D respirable air, this unit is equipped with a reliable electrochemical sensor that accurately indicates the level of carbon monoxide on an illuminated liquid crystal display. Adding versatility, this unit offers optional oxygen or dew point sensors for applications where detection or measurement is needed.

- Continuous Carbon Monoxide (CO) monitor

- Robust, easy to operate design

- Integrated dew point measurement

- Meets OSHA monitoring requirements for grade D breathing Air

- Automatic Calibration

- User Adjustable alarm points

- Dry Contacts for remote audible alarm and lights

- LCD display

- NEMA 4x housing

PREMIUM PLEATED & WRAPPED COMPRESSED AIR FILTERS

Next offers superior filtration from 1 micron to 0.01 micron, and connections from ½” NPT to 10” FLG. Next Filters are engineered to be efficient under any parameter. Next elements offer a durable element construction with an efficient drain layer to ensure continued performance after optimal element change periods.