High Pressure Regenerative Dryers 300 -10,000 PSIG

Modular Regenerative Dryer

The modular Next HMD heatless dryer offers a lightweight modular system that brings a durable and reliable solution to point of use and small compressed air applications where high-quality air is needed. They enable delivery of ISO Class 2 dew point to prevent corrosion, minimize production disruptions, and eliminate losses due to moisture or contamination in the compressed air supply.

The aluminum profile offers optimal flow conditions in the desiccant bed and ensures a safe pressure dewpoint. Next’s modular desiccant dryers are less than half the weight and size of a traditional twin tower design, allowing even the largest models to be easily maneuvered within its environment. The solid and rugged design of the HMD series provides efficiency, high reliability and trouble-free installation.

Advantages:

- Provides a constant outlet dew point in accordance with ISO8573-1 classes 2

- Uses dry use clean, dry purge air for regeneration, eliminating any risk of damage to the adsorption bed or re-contamination of the downstream compressed air

- No heat is used for regeneration; therefore, no insulation is required and loss of dew point on column changeover due to inefficient cool down is eliminated

HMD Series Features

- Completely Automatic

- Small footprint, light weight, advanced compact design

- Corrosion protected Aluminum column construction

- Slow re-pressurization prevents bed lifting, abrasion and extends desiccant life

- Heavy duty pneumatic valves

- Hassle free, reliable electronic controls

- Quiet enough to be placed in any work environment

- Easy installation, easy maintenance

- Lower Operating and Maintenance Costs

- Low Purge Loss of only 8-10%

- Lower Energy Consumption

- Easier and Faster Maintenance

- No Need to Heat and Cool Down Desiccant

- Significantly reduces noise level during depressurization and purge cycles constant flow and pressure

- Pressure is equalized before switching columns to ensure uninterrupted compressed air and consistent air pressure; equalization also ensures long desiccant life due to minimized desiccant attrition tower gauges

- High density filled desiccant provides maximum adsorption with lower dusting

- Easy to replace cartridges simplify maintenance requirements

- Uses integrated check valves and two pilot operated solenoid valves for proven performance and reliability

- Inlet, exhaust and outlet air are controlled using coaxial flow valves integrated into the upper and lower manifolds provide unrestricted flow capacity and designed for durability, ease of maintenance and long service life

HMD Controller Features

- Provides precision control of dryer operating cycle and visual indication of dryer status

- Operated by a robust and reliable microprocessor control system offering valuable features, including ‘power on’, ‘hours run’, and ‘service required’ indicators, memory retention built into the controller enables the controller to pick up where it left off in the drying cycle, ensuring consistently clean, dry air downstream.

- Set Time Cycle Control

- Regeneration Cycle Control

Standard Operating Voltage

- 110, 115V / 1 PH / 50-60 HZ

Control Panel Certification

- UL & CUL

Pre & Post Filtration (optional)

- Pre-filtration Grade 0.01 μm

- Post-filtration Grade 1 μm

Min/Max Ambient Air Temperature*

- 34/122° F

- 1.1 / 50° C

Average Purge Air*

- 15%

Outlet Pressure Dew Point

- -40° F / ° C

Min/Max Inlet Air Temperature

- 122° F

- 50° C

Pressure Vessel Certification

- CRN

Max Operating Pressure

- 60/200 Psig

- 4.1/13.7 Bar

Design Pressure

- 200 Psig

- 13.7 Bar

Dew Point Class

- Class 2 (ISO 8573-1)

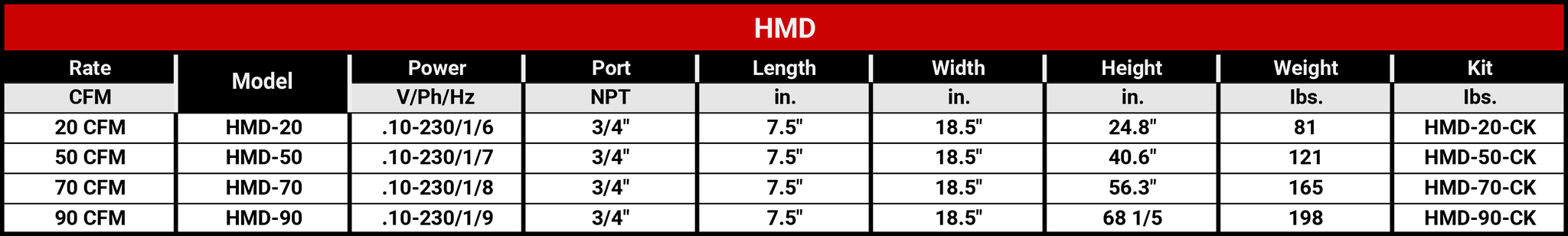

HMD Series Dryer Models

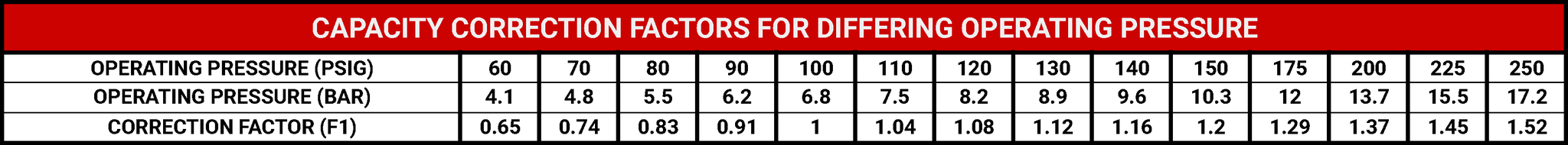

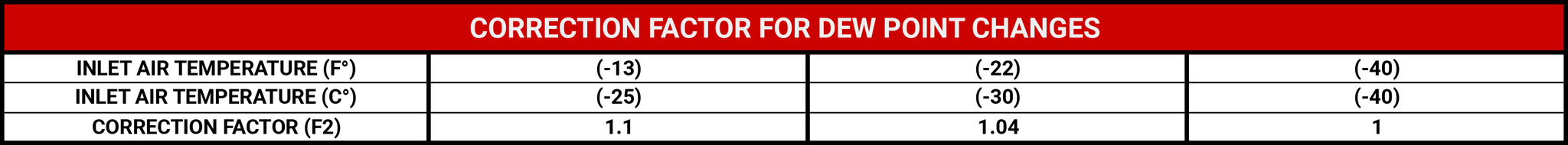

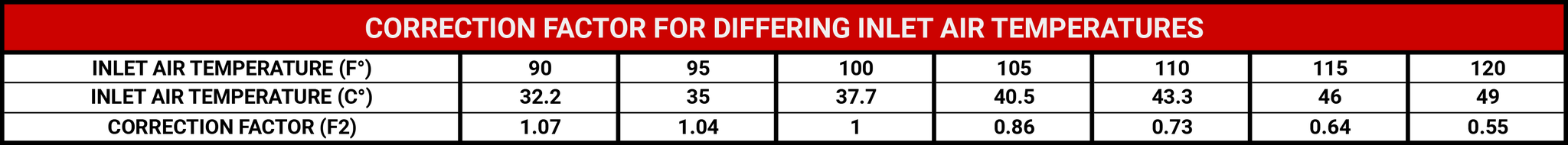

Correction Factors

*Additional Flows Available Upon Request

Sizing:

Air flow capacity = Operating Pressure x Inlet air Temperature

Correction Sample:

If a compressor delivers 70 scfm at 90 psi pressure with a 110°F inlet temperature, please choose your dryer model as follows:

(70 scfm / 0.91 / .86) = 90 scfm, therefore an HMD-90 would be needed.

HMD Optional Features

(If an option is not listed, please contact our sales team to accommodate any additional options.)

ALTERNATE VOLTAGES:

- ALT-V-1: 208-230 VOLTS / 1 PHASE / 50-60 HZ

CONDENSATE DRAIN:

- EFD: EXTERNALFLOAT DRAIN

- EZLD: ELECTRONIC ZERO LOSS DRAIN

- PZLD: PNEUMATIC ZERO LOSS DRAIN

- HPTD: HIGH PRESSURE TIMER DRAIN

Paired Image Link:

FILTRATION:

- Pre-filtration grade 0.01 μm

- Post-filtration grade 1.0 μm

CERTIFICATIONS:

- CE – CERTIFICATION

- CSA – CERTIFICATION

ADDITIONAL OPTIONS:

- Visual Moisture Indicator

- Dewpoint Monitor

- Energy Savings Control

- Tower Pressure Gauges

-100° F / -73° C (optional)

Your next step toward working with NEXT Air & Gas is to contact us for a Quote. Fill out the information below and give us the appropriate information needed to get started. Be sure to fill out all the contact information and our team will reach out with any questions or concerns.

If you’d rather speak to Sales Engineering, feel free to contact us at (865) 635-8178.

Below are links to product information and brochures. Please click and download at your convenience. If you have any questions or suggestions on materials you think would be helpful, please call us at (865) 635-8178.

Principle of Operation

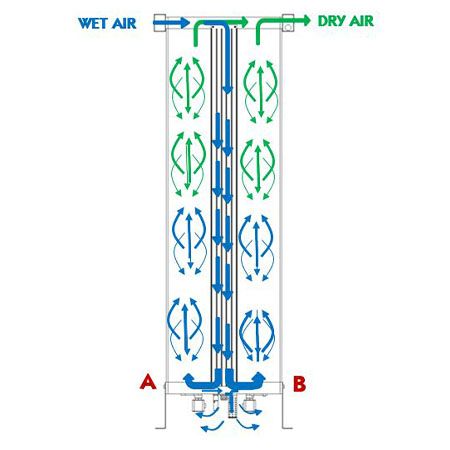

The HMD modular desiccant air dryers use the pressure swing adsorption principle to efficiently dry compressed air. They use a heatless twin tower configuration housed in a modular design. Each column contains a unique desiccant cartridge which incorporates an inlet water separator.

Clean, saturated air enters the dryer. The air is then directed into column A and compressed air travels through tower A for 2 minutes. Where the moisture vapor is adsorbed to-40°F pdp, or better ~20%, purge air expands through an orifice and regenerates tower B after 30 seconds, the purge exhaust valve closes and tower B repressurizes and is ready for adsorption to begin at the 2-minute mark (fixed cycle), tower A exhaust valve opens to regenerate. A Microprocessor controls all operations compressed air is expensive but nano dryers can be fitted with an energy savings device to save air and save money. By measuring pressure dew point, the microprocessor will extend the dryer cycle reducing compressor energy, wasted purge air and valve wear and tear.

Overview

Next Air & Gas Performance Advantages

The performance of any desiccant dryer depends on the quality of its key components. Next Air & Gas uses the best available valves, controllers and desiccant. With accurately designed and sized components, the dryers are manufactured to provide you with years of trouble-free operation.

Energy Saving Control

The Standard 10-minute cycle is designed for full load operating conditions and the standard purge rate of 15% is normally “consumed” regardless of whether the dryer is operating on full or partial load. Considerable energy savings can be obtained by reducing this purge loss in proportion to the real working conditions. A Probe Located on the dryer outlet, checks the pressure dew point and keeps the drying column working until the outlet compressed air reaches the chosen pressure dew point. The working cycles are now automatically modified, and the saving is direction proportional to the load reduction.

Quality Desiccant Media

Next Air & Gas uses a mixture of adsorption media in its heatless range of desiccant dryers to achieve consistent dewpoint. Activated Alumina, Molecular Sieve and Silica Gel are used in varying ratios depending on the application. The long lasting, high crush strength media has a very high surface/volume ratio. Beaded activated alumina is used as the adsorption media in heated desiccant dryers. The beads exhibit a very high internal surface area and high moisture separation efficiency. Each lot of desiccants is thoroughly tested for density, moisture content, abrasion resistance, surface area, mesh size and granule strength to assure that it meets strict design requirements.

Constant Flow and Pressure

Pressure is equalized before switching columns to ensure uninterrupted compressed air and consistent air pressure. Equalization also ensures long desiccant life due to minimized desiccant attrition.

Maximum Corrosion Protection

High tensile aluminum columns are alocrom protected then externally powder coated to provide maximum protection for corrosive environments.

Dual-Core Construction

Exclusive Dual-Core design contributes to even and equal flow pass through each desiccant tube and desiccant bed. Avoid desiccant dusting and Channeling-Effect which likely happens in other traditional desiccant dryers, will cause lousy performance on Pressure Dew Point. Furthermore, dust and wet air definitely will lead to the severe damage to air equipment. Dual-Core Modular design solves these problems and maintains a constant performance on PDP-40°C /-40°F.

Dual-Core desiccant tubes are perfectly secured with bottom and top manifold and the sophisticated construction design can help the flow pass with minimum resistance. It all lead to minimum pressure drop and minimum purge lost compared to traditional desiccant dryers.

Anti-Leakage

Leakage is always the potential risk for traditional modular dryers due to compact and manifold construction. Dual-Core design can give double warranty to prevent leakage. Dual-Seal, Dual-Pressure-Hold, and Dual-Anti-Leakage contributes to more energy saving and stability.

PREMIUM PLEATED & WRAPPED COMPRESSED AIR FILTERS

Next offers superior filtration from 1 micron to 0.01 micron, and connections from ½” NPT to 10” FLG. Next Filters are engineered to be efficient under any parameter. Next elements offer a durable element construction with an efficient drain layer to ensure continued performance after optimal element change periods.