NMPF Series

Filtration - Mid Pressure Line

The Next NMPF mid pressure range filter series are certified CRN and manufactured and tested in accordance with ISO 8573 standards. The NMPF filters have (4) ranges of efficiencies, removing contaminants as small as 0.01 microns at up to 580 psi – ½” to 1” NPT sizes. A protected auto float drain (0.07” orifice) is standard for optimal and reliable removal of liquid contaminants. It’s 2-part permeant pressure cast molded aluminum housing goes through the process of chromo phosphate and externally powder coated. Low pressure drop is achieved through optimal flow path design.

The high efficiency bowl and non-turbulent lower filter zone assure that no condensate gets re-entrained in the air stream. The NFA’s seal cannot be opened while the filter is under pressure, offering additional efficiency. The stop lock feature design allows for easy disassembly and element changeout but also prevents over tightening of the filter body.

- Dust Particles (from Ambient air and/or desiccant)

- Liquid Water and Moisture Vapor

- Liquid Oil and Oil Vapor

- Hydrocarbon Vapor

- Rust Particles

- Pipe Scale

- Acidic condensates

Your next step toward working with NEXT Air & Gas is to contact us for a Quote. Fill out the information below and give us the appropriate information needed to get started. Be sure to fill out all the contact information and our team will reach out with any questions or concerns.

If you’d rather speak to Sales Engineering, feel free to contact us at (865) 635-8178.

Below are links to product information and brochures. Please click and download at your convenience. If you have any questions or suggestions on materials you think would be helpful, please call us at (865) 635-8178.

Cause

Liquid water entering refrigerated air Dryers.

Effect

Inefficient dryer operation leading to higher cost and/or inability to meet dewpoint. Damage to refrigerated dryer components such as heat exchangers.

Resolution

Install moisture separator after air compressor and coalescing prefilter before air dryer.

Cause

Liquid water entering desiccant regenerative air Dryers.

Effect

Inability to meet targeted dew point. Damage to dryer components such as the corrosion and lifespan of valves and desiccant media.

Resolution

Install moisture separator after air compressor and coalescing prefilter before air dryer.

Cause

Hydrocarbon and/ or oil vapors entering process airstream

Effect

Product spoilage. Odor and/ or taste in process air.

Resolution

Install high efficiency carbon filter after air dryer.

Cause

High pressure drop across compressed air filtration.

Effect

Increased energy consumption to maintain pressure. Low line Pressure leading to inefficient operation of down stream equipment.

Resolution

Install filters with housings and elements engineered for low pressure drop. Replace elements at optimum point to keep both maintenance and energy costs at minimum

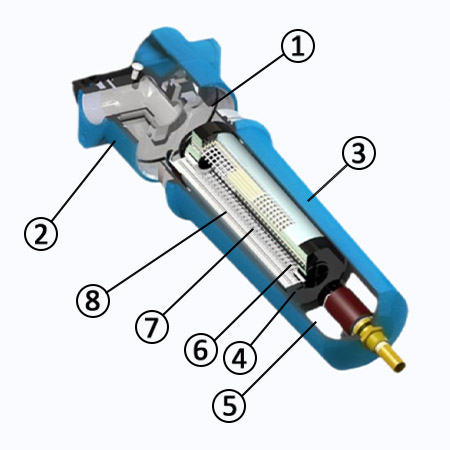

- Differential pressure gauge

- O-ring bowl seal

- Diecasting aluminum housing chromated with polyester epoxy powder coating for corrosion resistance

- Large capacity reservoir allow large condensate volume

- Auto drain

- Drainage layer

- High efficiency filtration media

- Support cylinder

Compact & Lightweight

Advanced housing and element design prove a smaller, more compact and light weight filter which is efficient and easy to maintain.

Stop Lock Feature

A high-quality differential pressure indicator is used to identify pressure differential

Filter Connections

More port sizes are available to match both pipe size and system flow rate giving additional customer choice.

Fully Corrosion Protected

Anodized cast aluminum and powder coated with epoxy finish for full corrosion protection.

Particulate Filters: F & FR Elements

High-efficiency particulate filters remove particles to 1 Micron, including coalesced liquid water and lubricants. Maximum remaining aerosol content after filtration is 0.5 ppm at 70°F

Next Family of Filtration

Next offers superior filtration from 1 micron to 0.01 micron. Durable element construction and an efficient drain layer ensure continued performance after optimal element change periods.

Vapor Removal: C Elements

Next filters use activated carbon to remove lubricant and hydrocarbon odors. Post filtration, remaining vapor content is less than 0.003 ppm (excluding methane.) This filter installation should always be preceded by high efficiency filter grades.

High Pressure: HPH & HPR Elements

Next’s high-pressure filter lines consist of the NFHP with pressures up to 580 psig and the SHP series up to 6091 psig. From flows from 35 to 421 cfm.

High Temp: FRHT Elements

Next high-temperature filters are available up to 250 °F in the NFX Series

Coalescing Filters: H & HR Elements

For maximum filtration, next offers compressed air filters to remove particulate down to 0.01 micron, including water and oil aerosols, providing a maximum remaining oil aerosol content of 0.01ppm at 70°F, when used with Next particulate filters