NRD-NCE & NCP Series

Refrigerated Compressed Air Dryers

The NEXT Pure-Stream NRD-NCE & NCP non-cycling refrigerated dryer offers the highest efficiencies at various flow conditions in an economical efficient design. The refrigerated series dryers are engineered with high-efficiency variable flow technology, which allows for desired dew points regardless of flow variation.

A Premium non-cycling refrigerated dryer designed with high efficiency, durability, and energy saving. The new and innovative digital controller allows the user to control the entire dryer functionality, from the simplest to the most common engineer’s complex functions, such as hard alarms (high and low temperature).

The dryer series is focused on reliable, constant dew point performance in all flow conditions. With their excellent heat transfer coefficients and extremely low pressure drop, these dryers will outperform the competition in protecting your compressed air system, machinery and tools; and will improve your manufacturing processes.

Through Optimization of the critical dryer elements heat exchanger, separator and condensate removal the Next engineers developed a system that ensures highest performance at full and partial speed conditions to always protect your application.

ADVANTAGES

- Lower pressure drop even with load variances

- Low power consumption thanks to patented aluminum heat exchanger, high efficiency compressors, and innovative hot gas bypass valve.

- Constant dew point with differing load conditions

NRD-NCE & NCP Series Features

- Economical compact design

- Energy Savings

- Dual Sensor System

- Dew Point stability at 40° F / C

- Programmable Electronic Condensate drain

- Eco-friendly gasses and recyclable material

- Thermal Protection Switch

- Green sustainability focused R134a refrigerant

- Low pressure drops and energy efficiency.

- Easy installation and start up.

- Fully adjustable and extremely durable timer drain as standard

- Hermetically sealed compressors

- Flat plate Aluminum Heat exchangers

Controller Features

- User Friendly

- Dew point monitoring

- Drain Management

- Alarm Management

- Automatic restart after power loss

- Service reminder alarm

Standard Operating Voltage

- 115V / 1 PH / 60 HZ – Standard (15 to 175 CFM)

- 208-230 VOLTS / 1 PHASE / 50-60 HZ (220-400 CFM)

- 460 VOLTS / 3 PHASE /60 HZ (500 -3,000 CFM)

Electrical Certification

- UL, CUL

ISO Dew Point Class:

- Class 5 (ISO 8573-1:2010) (NCE Series)

- CLASS 4 (ISO 8573-1) (NCP Series)

Refrigerant

- R134a (15 to 150 CFM)

- R407c (175 to 3,000 CFM)

Max Operating Pressure

- 200 psig

- 14 bar

Min/Max Design Pressure

- 100-232 psig

- 7-16 bar

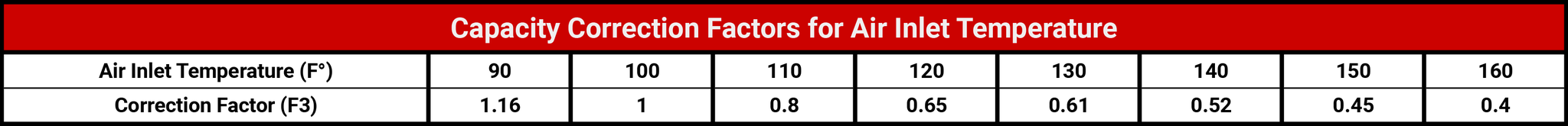

Inlet Air Temperature

- 100° F /C

- 38° F /C

Max Operating Temperature

- 120° F

- 49° C

Max Ambient Air Temperature

- 100°F

- 38° C

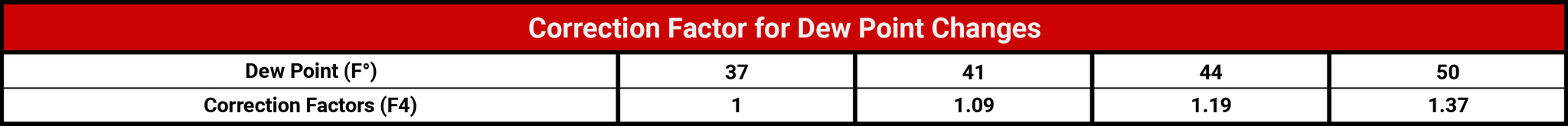

Standard Outlet Pressure Dew Point

- 36 to 39° F /C

- 2 to 4° C

Connection Type

- ¾”NPt to 6” FLG

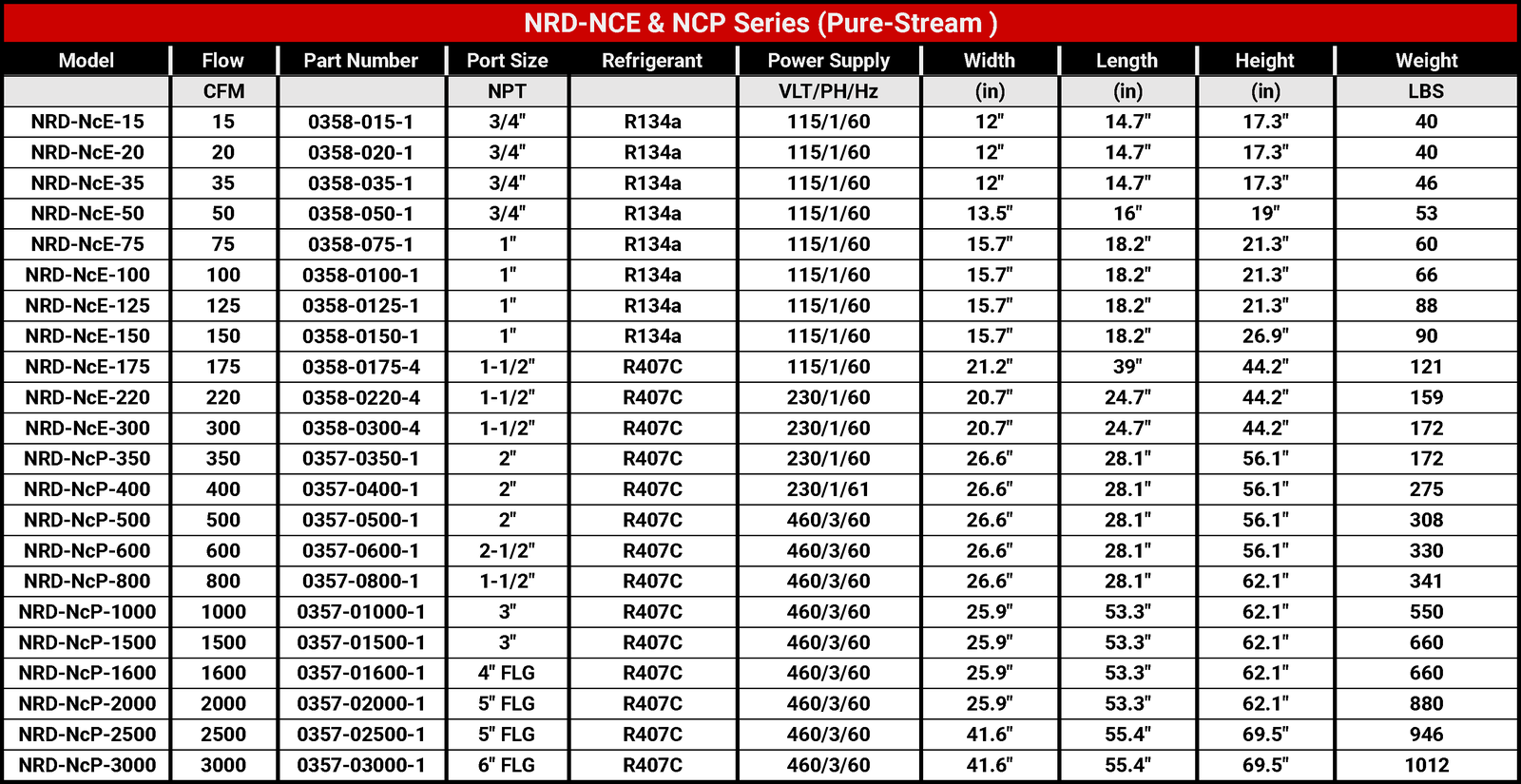

Model NRD-NCE Series Dryers

NCE Series

NCP Series

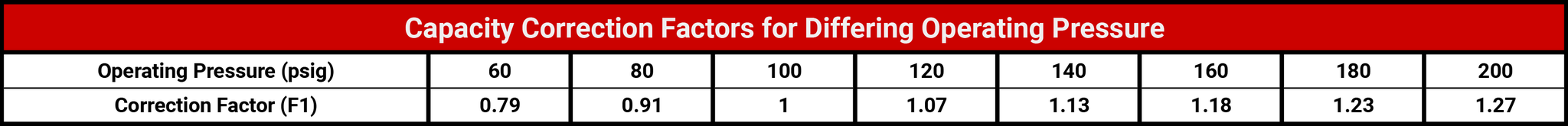

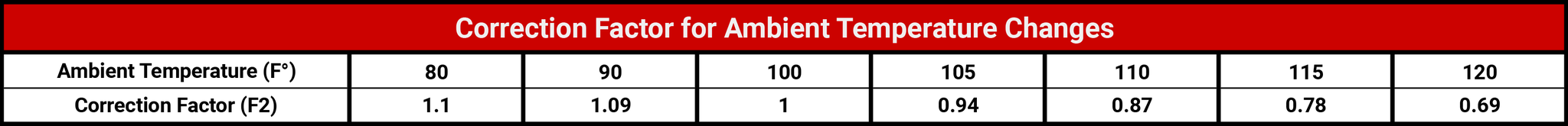

Sizing:

Air Flow Capacity = Operating Pressure x Inlet Air Temperature

Correction Sample:

If a compressor delivers 425 scfm at 75 psi the dryer inlet temperature is 110 F and ambient temperature is 105 f please choose your dryer model as follows: (425 scfm / 0.85 /0.75 / 0.96 ) = 695 scfm, Therefore an NCP-700 would be needed.

NRD-NCE & NCP Series Options

All refrigerated dryers come standard with a durable timer drain. A truly unique Electronic “NBM” and manual “NFD” zero loss drain is offered as an option. With the zero-loss drain, condensate is collected in a chamber, segregated from the air flow. As condensate builds, it activates a drain level sensor / float within its chamber. This opens an external solenoid / float drain to evacuate the condensate, closing the valve again before any air escapes. The drain cycle continually adjusts itself to working conditions.

CONDENSATE MANAGEMENT +

Electronic Zero Loss Drain

NBM- Series

Manual Zero Loss Float Drain

NFD- Series

Filtration +

NFA- Series

- Pre-filtration grade μm 0.01

- Post-filtration grade μm 1.0

Next’s NFA Compressed Air Filters with High Performance Elements option is critical for optimum performance and efficiency

Water Cooled

NCP-W SERIES

- 800-1600 CFM Enclosed

- 2000+ CFM Open Frame

*Please Note: The NCP-W series are engineered to order. Please contact the factory for additional information.

Construction

- TWO VALVE BY-PASS

- THREE VALVE BY-PASS

- RUGGED ENCLOSED SKID

Region Specific Specifications

(EMEA, LATIN AMERICA, ASIA, AUSTRALIA)

ALTERNATE VOLTAGES

230/1/50-60 & 400/3/50-60

ALTERNATE CONNECTIONS

2” BSP-F TO DN200

REGION CERTIFICATION

CE, EAC, UKCA, CSA,

Your next step toward working with NEXT Air & Gas is to contact us for a Quote. Fill out the information below and give us the appropriate information needed to get started. Be sure to fill out all the contact information and our team will reach out with any questions or concerns.

If you’d rather speak to Sales Engineering, feel free to contact us at (865) 635-8178.

Below are links to product information and brochures. Please click and download at your convenience. If you have any questions or suggestions on materials you think would be helpful, please call us at (865) 635-8178.

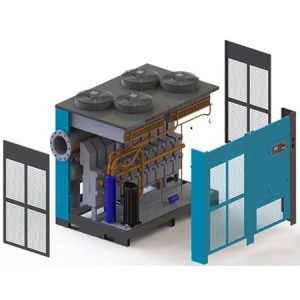

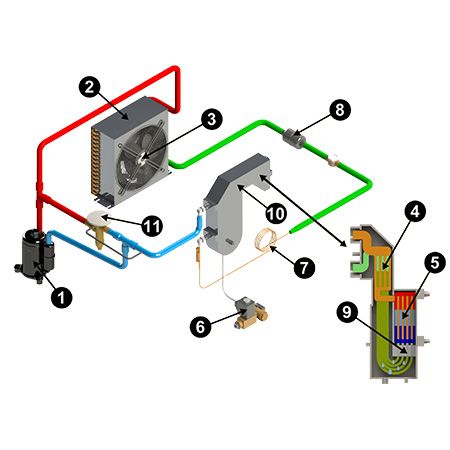

Open View

NCE- Series

- Controller

- Fan Motor

- Heat Exchanger

- Condenser

- Filter Dryer

- Valve Strainer

- Solenoid Valve

- Capillary Tube

- Compressor

- Hot Gas By-Pass Valve

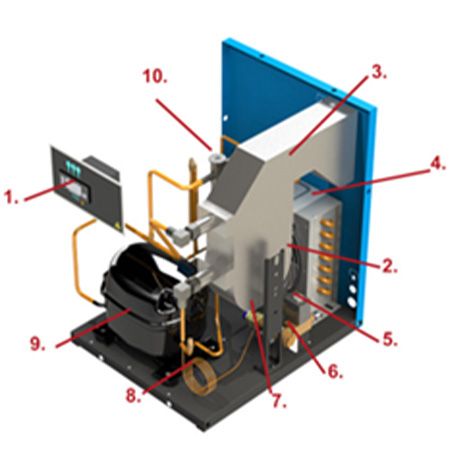

NCP- Series

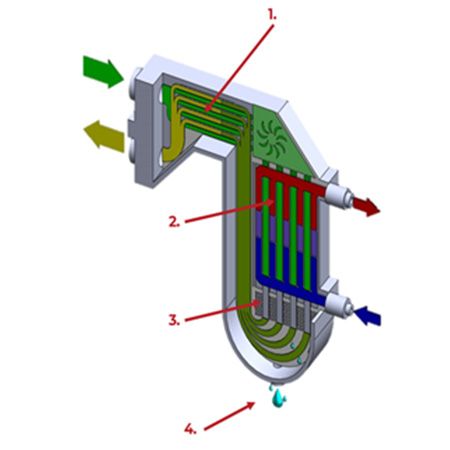

Operation

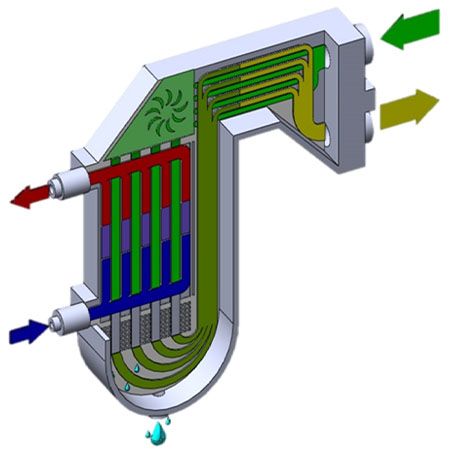

- Saturated compressed air enters the system and is precooled in the air/air heat exchanger.

- Then, precooled air moves downstream through the air/refrigerant heat exchanger. The heat exchanger’s vertical profile design reduces condensed moisture by nearly 99% using gravitational force.

- To reliably prevent separated droplets from reentering the airstream, condensate collects in a large reservoir with subsequent recirculation where flow velocity is significantly reduced.

- Accumulated condensate is then discharged from the dryer via drain. The dried, cold process air passes back through the heat exchanger to be reheated — reducing relative air humidity and recovering up to 60% cooling capacity.

Non-Cycling dryers are ideal for running at full load because they maintain a constant energy consumption no matter the flow and air demand. Next’s NRD-NCE & NCP non-cycling dryers use a hot gas bypass to maintain a stable dew point in varying operating conditions and control the amount of refrigerant circulating through the dryer.

Refrigeration Circuit

- Compressor

- Condenser

- Fan Motor

- Air to Air Heat Exchanger

- Evaporator

- Condensate Discharge Valve

- Capillary Tube

- Dryer Filter

- Demister

- Ultra Compact Heat Exchanger

- Hot Gas By-Pass Valve

Next Air & Gas Performance Advantages

The performance of any desiccant dryer depends on the quality of its key components. Next Air & Gas uses the best available valves, controllers and desiccant. With accurately designed and sized components, the dryers are manufactured to provide you with years of trouble-free operation.

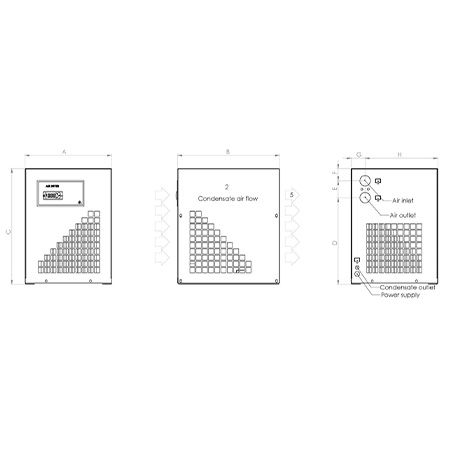

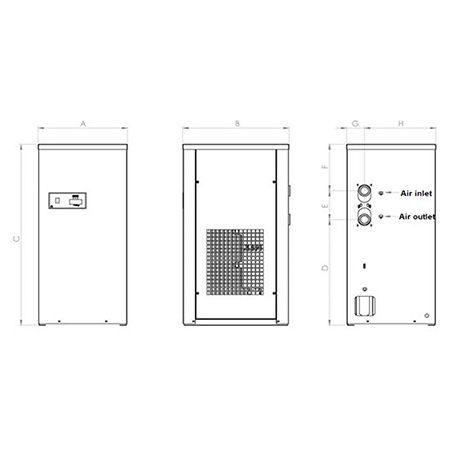

Vertical Heat Exchanger Design

The patented aluminum heat exchanger has been designed to offer maximum performance and minimum pressure drop. The unique heat exchanger is both an air-to-air heat exchanger as well as an air-to-refrigeration heat exchanger. The warm and humid air is pre-cooled by the cool dry air that is leaving the dryer, which increases efficiency.

The air-to-air and the air-to-refrigerant heat exchangers plus the demister type condensate separator are housed in a unique module. The module has a vertical flow layout ensuring a natural facilitated down flow of the wet compressed air to the condensate drain. The counter flows of compressed air ensure maximum heat transfer.

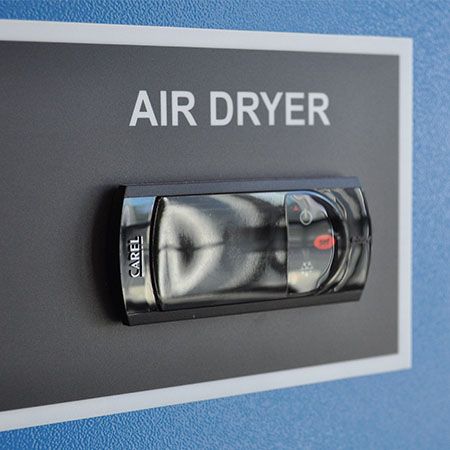

Digital Controller

All models have a digital controller, with a double sensor system that keeps the dew point and condensing pressure within ideal operating parameters.

The controller features a 3-digit display for the visualization of the Dew Point temperature (in °C or °F).

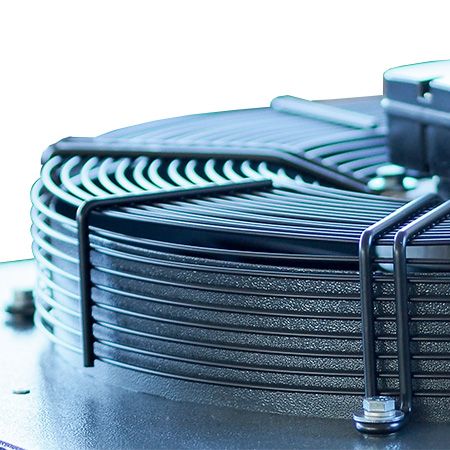

Cooling

Generous sizing of the condenser unit ensures maximum performance of the refrigerant circuit and the ability to operate with changes in ambient conditions quickly. Access to the condenser for cleaning and maintenance is simple. The generous sizing of the condenser ensures maximum performance of the refrigerant circuit and the ability to operate with changes in ambient conditions.

Refrigeration Compressor

Circulation of the refrigerant in the cooling system is achieved through a variety of highly efficient types of compressors; piston (reciprocating), Rotary, and Scroll type.

Hermetic Reciprocating

(Used in NCE-15-50)

Hermetic compressors are dependable, cost-effective, and incredibly versatile. An ideal choice for various air conditioning applications, these compressors can withstand harsh environments and have extended operating life cycles. This compressor is suitable whether you’re looking for a dependable unit that saves on costs or a versatile option to meet your needs.

Rotary Compressors

(Used in 75-176 CFM)

Compression of the refrigerant is achieved by way of interaction between a cylindrical stator and a rotating eccentric nucleus. In this method, the parts which come into

contact with one another is wear-resistant and therefore more reliable.

Scroll Compressors

(Used in 200-3,000 CFM)

The type of compressor used is the scroll. Widely used in the air conditioning and refrigeration sectors, the scroll compressor performs well and has low energy consumption. Compression of the refrigerant is achieved by way of two concentric coils: one fixed and the other rotating. The scrolls are wear-resistant, highly reliable and guarantee a high level of noise reduction.

Hot Gas Bypass Valve

The precise and accurate hot gas bypass valve prevents the formation of ice inside the evaporator at any load condition. The valve is set during the final test and no further adjustments are required.

Condensate Drain Controls

NRD-NCE & NCP dryers are equipped with a timed solenoid condensate drain. The timed condensate drain is the most economic and efficient method of discharging unwanted condensate from compressed air systems.

Removal of condensate from compressed air systems is a critical maintenance requirement. Failure to carry out regular draining results in serious disruption to production schedules, deterioration in product quality, damage to sensitive pneumatic equipment, etc. The auto drain eliminates the risk of human error and possible costly aftermath by providing regular system drainage.

- Adjustable time scales to suit any condensate discharge times:

- ON Time: 0.5 – 10Sec

- OFF Time: 0.5 – 45Min

- Drain test switch to check functionality of unit

- Yellow LED’s to indicate status