NDR-NCP Series

Desiccant Compressed Air Dryers

The NEXT Pure-Stream NcP (330-3,000 CFM) offers the highest efficiencies at various flow conditions in a lightweight, minimal-footprint design. The NcP series dryers are designed with high-efficiency variable flow technology, which allows for desired dewpoints regardless of flow variation.

A Premium Non-cycling refrigerated dryer designed with high efficiency, durability, and energy saving. The new and innovative digital controller, developed by Next, allows the user to control the entire dryer functionality, from the simplest to the most common engineer’s complex functions, such as hard alarms (high and low temperature).

- Economical design

- Energy Savings

- Dual Sensor System

- Low Pressure Dro

- Dew Point stability at 40° F

- Programmable Electronic Condensate drain

- Eco-friendly gasses and recyclable material

- Thermal Protection Switch

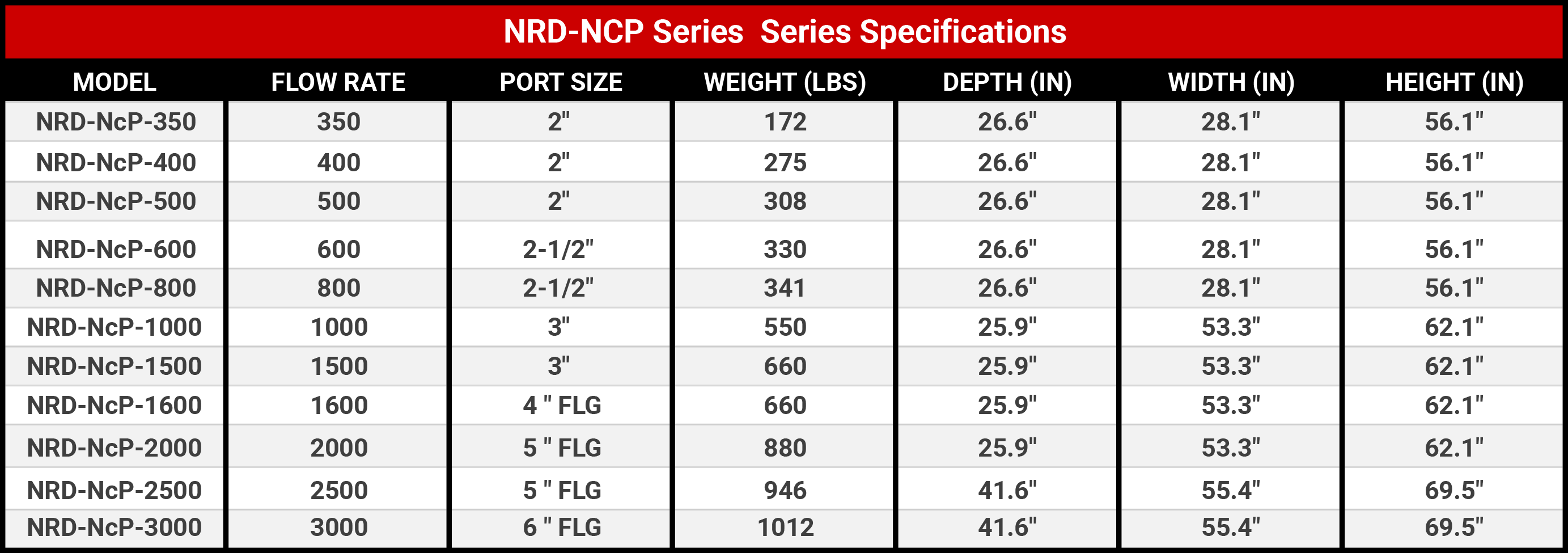

Model NDR-NCP Series Dryers

- Aqua-Pure Zero Loss Eco drain

- Pre & After Filtration (ships loose)

- Two Valve By-Pass

- Alternative Voltages

Your next step toward working with NEXT Air & Gas is to contact us for a Quote. Fill out the information below and give us the appropriate information needed to get started. Be sure to fill out all the contact information and our team will reach out with any questions or concerns.

If you’d rather speak to Sales Engineering, feel free to contact us at (865) 635-8178.

Below are links to product information and brochures. Please click and download at your convenience. If you have any questions or suggestions on materials you think would be helpful, please call us at (865) 635-8178.

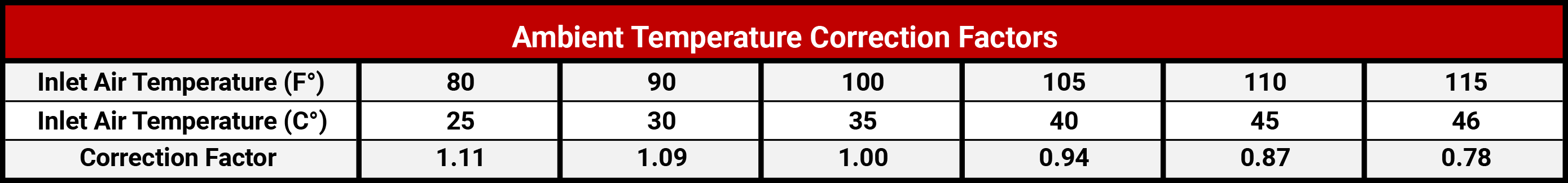

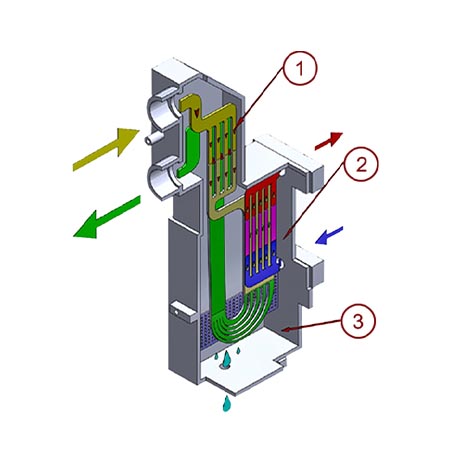

Operation

- Saturated, compressed air is cooled in the air-to-air heat exchanger.

- The pre-cooled air passes through the evaporator where it is cooled to required temperature.

- The Condensate, separated from the compressed air in the demister, is discharged automatically by the condensate drain.

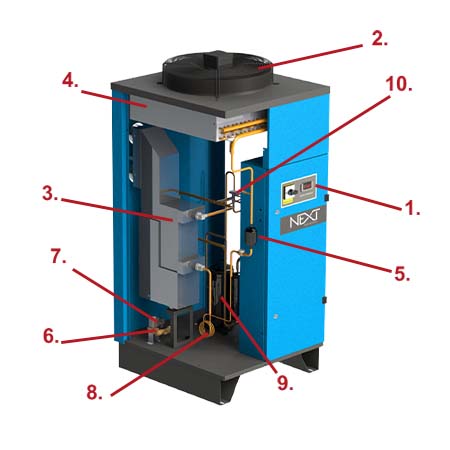

Open View

- Controller

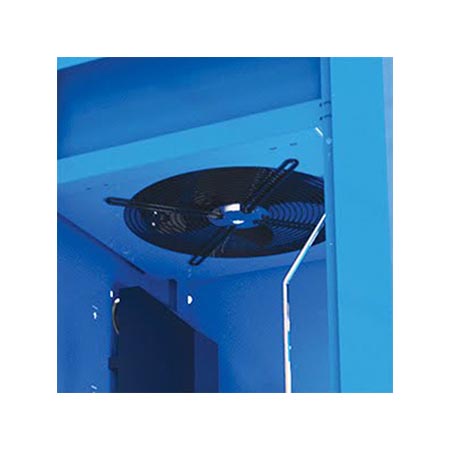

- Fan Motor

- Heat exchanger

- Condenser

- Filter Dryer

- Valve Strainer

- Solenoid Valve

- Capillary Tube

- Compressor

- Hot gas by-pass valve

Additonal Information

Vertical Heat Exchanger Design – The patented aluminum heat exchanger has been designed to offer the maximum performance and minimum pressure drop. The unique heat exchanger is both an air-to-air heat exchanger as well as an air to refrigeration heat exchanger. The warm and humid air is pre-cooled by the cool dry air that is leaving the dryer, which increases efficiency.

Digital Controller – All models have a digital control board, with a double sensor system that keeps the dew point and condensing pressure within ideal operating parameters.

Condenser Cooling | Coils – Generous sizing of the condenser unit ensures maximum performance of the refrigerant circuit and the ability to operate with changes in ambient conditions quickly. Access to the condenser for cleaning and maintenance is simple.

Refrigeration Compressor – The circulation of the refrigerant in the cooling system is done through the highly efficient refrigerant compressor. Thanks to its innovative construction, this has reduced energy consumption and increased reliability levels.

Condensate Drain Controls – NCE dryers are equipped with an electronic drain valve which is controlled by the programmable controller. The complex digital controller ensures timely draining of the condensation, but also allows for easy programming and testing of the drain valve