NRD-TM Series (6,000-30,000 CFM)

THERMAL MASS HIGH CAPACITY Refrigerated Compressed Air Dryers

The NRD-TM Thermal Mass High-capacity refrigerated air dryer combines the advantages of a direct thermal exchange with thermal storage. It’s two dryers in one. By combining these two powerful energy-saving technologies the NRD-TM provides you with the lowest power consumption available in the market today. This cutting-edge concept not only reduces your energy bill, it also offers steady dew point performance and reliable operation to ensure you have continuous, worry free, clean and dry compressed air.

With unique digital controls that automatically manage energy consumption and energy saving condensate drains that automatically adjust to demand – the NRD-TM cycling dryer saves energy and eliminates seasonal adjustments. It is the ultimate solution to remove moisture from your compressed air system.

Refrigerated dryers must be sized to handle the worst-case operating conditions they may encounter – the highest possible flow at the hottest possible inlet temperature on the highest day of the year. The power consumption needed to operate in these worst-case conditions is far greater than otherwise needed. Dryer demand is a function of both required air flow and ambient conditions. The NRD-TM takes advantage of this savings opportunity by significantly reducing power consumption to match actual demand.

NRD-TM Series Features

- Zero-purge drain system

- Pump pressure gauge

- Thermal storage temperature gauge

- Phase protection module

- High Temp module

- Pump failure indicator

- No-Flow indicator

- Pump starter with overload protection

- Compressor starter with overload protection

- Inlet Temperature Indicator

- Outlet temperature indicator

- Refrigerated discharge pressure

- Compressor sequencer (for units with multiple compressors)

- Pump Separator (for units with duplex pumps)

- Compressor on indicator

- Air inlet pressure gauge

- Air outlet pressure gauge

- Nema-12 Electrical Enclosure

Standard operating Voltage

- 460V / 3 PH / 60 HZ – Standard

- 575V / 3 PH / 60 HZ – Optional+

- 400-380V / 3 PH / 50 HZ – Optional+

COMPRESSOR TYPE

- NRD-TM-2500 To 5,000 (SCROLL)

- NRD-TM-6,000+ (SEMI-HEMTIC

HEAT EXCHANGER TYPE

- NRD-TM-2500 To 500 (STAINLESS STEEL -Plate)

- NRD-TM-10,000+ (SHELL & TUBE) ASME

Min/Max inlet air temperature

- 40 to 120 ° F

- 40 to 49 C

Design Pressure Range:

- 0 to 150 psig

- 0 to 14 bar

Design Ambient temperature

- 40 to 110° F

- 4 to 43° C

Condenser Cooling Options

- Water Cooled (Standard)

- Air Cooled (Optional+)

Refrigerant Type

- R404a

- R407C

Control Panel Enclosure

- NEMA 12

System Pressure Drop

- 5 to 4.5 Psig

- .2 to .3 Bar

Standard outlet pressure Dew Point

- -40° F / C

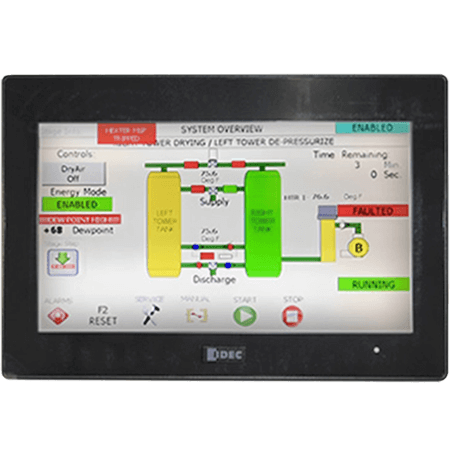

Controller

- 7” HMI Touch Screen Controller

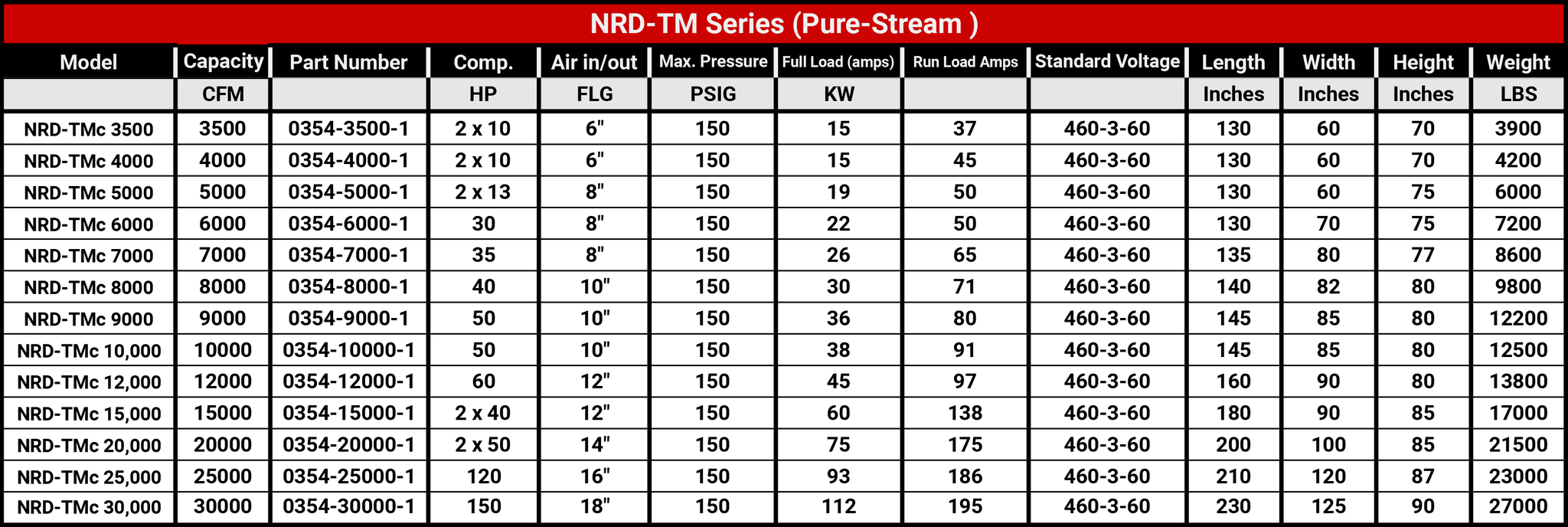

Model NDR-TM Series Dryers

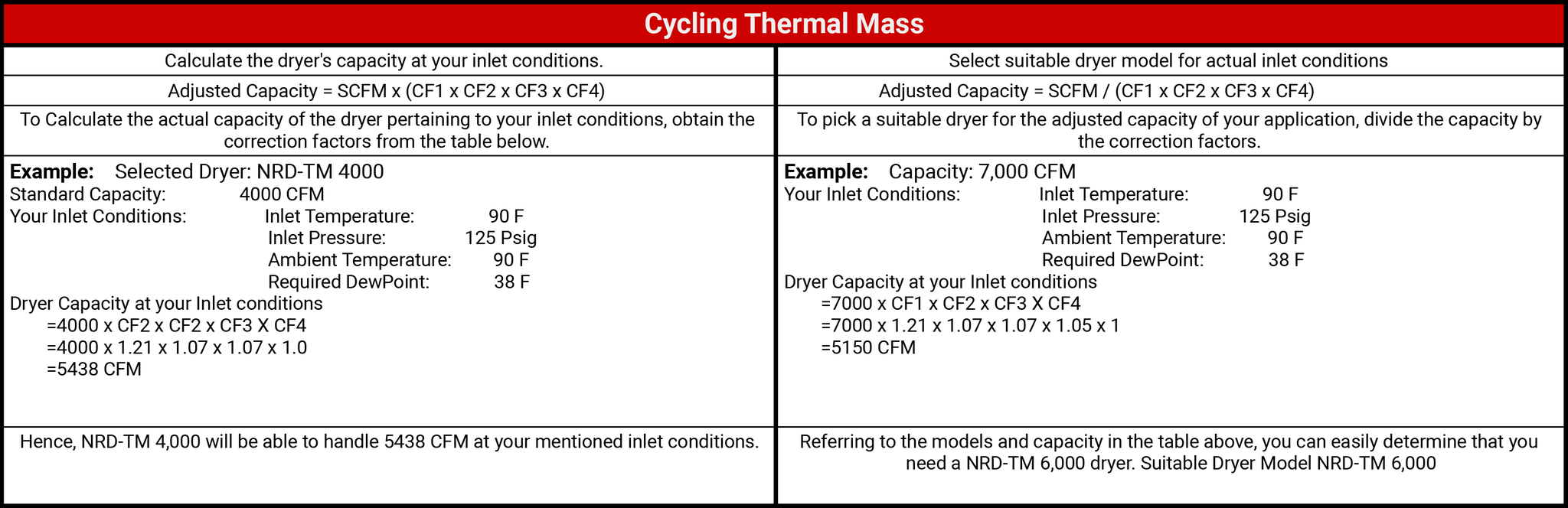

Dryer Sizing

Calculate the dryer’s capacity at your inlet conditions

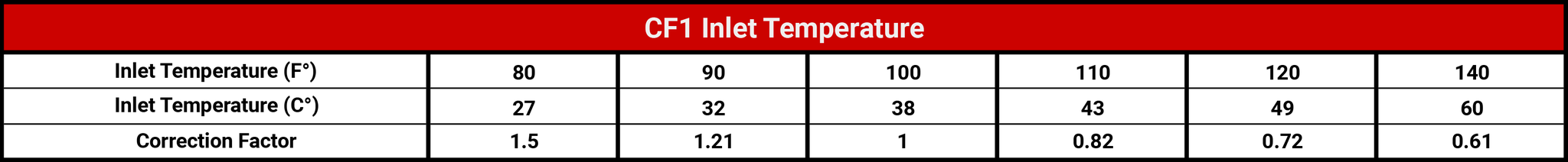

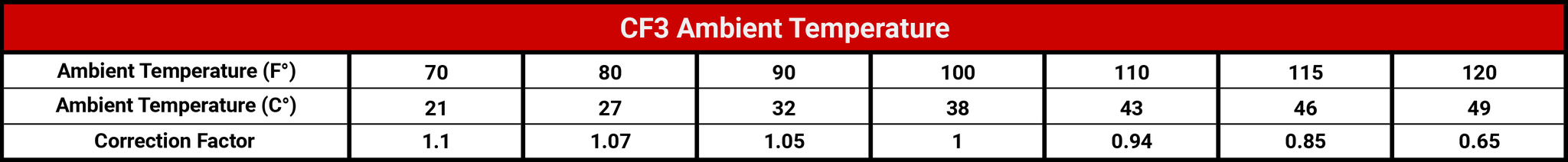

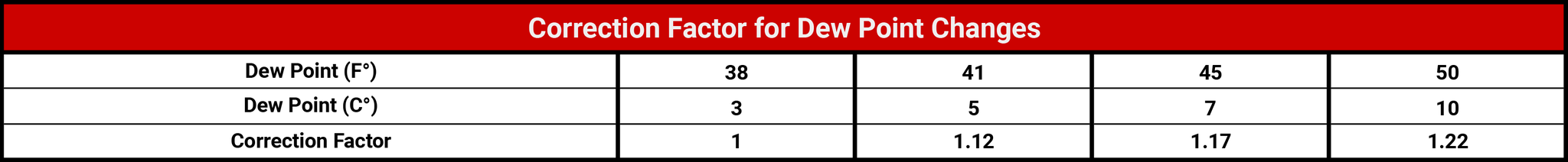

Adjusted capacity = SCFM x (CF1 x CF2 x CF3 x CF4)

To calculate the actual capacity of the dryer pertaining to your inlet conditions, obtain the correction factors from the table above.

Example:

Selected Dryer: NRD-TM-4000

Standard Capacity: 4000 SCFM

Inlet Conditions:

Inlet temperature: 90 F

Inlet pressure: 125 psig

Ambient Temperature: 90 F

Required Dew point 38 F

Dryer Capacity at your inlet Conditions

= 4000 x CF1 x CF2 x CF3 x CF4

=4000 X 1.21 x 1.07 x 1.05 x 1.0

= 5438 CFM

Hence, a NRD-TM-400 will be able to handle 5438 CFM at the mentioned inlet conditions

Adjusted capacity = SCFM / (CF1 x CF2 x CF3 x CF4)

To pick a suitable dryer for the adjusted capacity of your application, divide the capacity by the correction factors:

Example:

Capacity: 7000 SCFM

Inlet Conditions:

Inlet temperature: 90 F

Inlet pressure: 125 psig

Ambient Temperature: 90 F

Required Dew point 38 F

Dryer Suitable for your inlet and flow

= 7000/ (CF1 x CF2 x CF3 X CF4)

=7000/ (1.21 x 1.07 x 1.05 x 1)

=5150 CFM

Referring to the models and capacity in the table above, you can easily determine that you need a 6000 NRD-TM dryer

Suitable Dryer Model NRD-TM 6000

To calculate the actual capacity of the dryer pertaining to your inlet conditions, obtain the correction factors from the table above.

Example:

Selected Dryer: NRD-TM-4000

Standard Capacity: 4000 SCFM

Inlet Conditions:

Inlet temperature: 90 F

Inlet pressure: 125 psig

Ambient Temperature: 90 F

Required Dew point 38 F

Dryer Capacity at your inlet Conditions

= 4000 x CF1 x CF2 x CF3 x CF4

=4000 X 1.21 x 1.07 x 1.05 x 1.0

= 5438 CFM

Hence, a NRD-TM-400 will be able to handle 5438 CFM at the mentioned inlet conditions

NRD-TM Series Options

- Duplex Pumping

- Multiplex Compressor

- Air-Cooled Condenser

- Remote condenser

- Compressor sequencer

- Three Valve By-Pass

- Mounted Pre & After Filtration

- Digital Dew Point Monitor

- Nema-4,12,7 electrical enclosure

Your next step toward working with NEXT Air & Gas is to contact us for a Quote. Fill out the information below and give us the appropriate information needed to get started. Be sure to fill out all the contact information and our team will reach out with any questions or concerns.

If you’d rather speak to Sales Engineering, feel free to contact us at (865) 635-8178.

Below are links to product information and brochures. Please click and download at your convenience. If you have any questions or suggestions on materials you think would be helpful, please call us at (865) 635-8178.

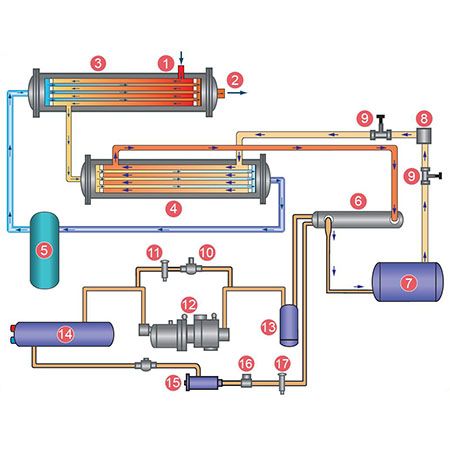

Principle of Operation

Hot saturated air from the aftercooler enters the air/air heat exchanger, where the air is pre-cooled by the cold, dry air leaving the heat exchanger. The pre-cooled air then enters the air/glycol heat exchanger, where it is cooled to its final dew point by chilled water/glycol, flowing in the counter-current through the shell. The chilled air passes through the moisture separator, which has a high efficiency of separation for different flow rates. Condensate is removed from the system without any loss of air via a zero purge drain valve. Finally, the cold, dryer air is reheated in the air/air heat exchanger by the incoming hot air for maximum volumetric efficiency before exiting the dryer. The water/glycol is chilled by a cycling refrigeration system and continuously pumped through the shell side of the air/glycol heat exchanger. The glycol flow rate remains constant, regardless of compressed air load. The refrigeration compressor unloads and / or cycles OFF when pre-set temperature is reached for water glycol, thus minimizing electrical power consumption.

- AIR INLET

- AIR OUTLET

- PRE-COOLER /RE-HEATER

- AIR TO AIR / GLYCOL HEAT EXCHANGER

- MOISTURE SEPARATOR

- EVAPORATOR

- COLD BANK STORAGE

- PUMP

- ISOLATION VALVES

- SOLENOID VALVE

- DEFROSTER

- COMPRESSOR

- SUCTION ACCUMULATOR

- CONDENSER

- FILTER DRYER

- SIGHT GLASS

17. THERMOSTATIC EXPANSION VALVE

NRD-TM Design Advantages

Next uses the most energy efficient components in the manufacture of these high-capacity Refrigerated Dryers. The dryers are custom-built to suit your design and application requirements

Compressors

Rotary Screw Compressor

Semi Hermetic Reciprocating Compressor

High Efficiency Scroll Compressor

Air Cooled Condenser

Air cooled condensers are constructed from high thermal efficiency copper tubes, coils and aluminum fins and are rated for 100 F ambient temperature.

NEMA Rated Electrical Enclosure

NEMA 12 enclosures are standard on all high capacity refrigerated dryers. Optional Controls , monitoring systems, indicators and NEMA 4, 4X, and NEMA 7 Enclosures are also available as an Option.

Separators

High efficiency centrifugal separators eliminate moisture from the air system. The unique design of the separator removes 99% of the water droplets with no mechanical movement and maintenance.

Water Cooled Condenser

Water cooled condensers are designed according to ASME standards with carbon steel shell and copper tubes to provide adequate cooling capacity that exceeds the refrigeration demand. They are equipped with head pressure control and energy saver water regulating valve.

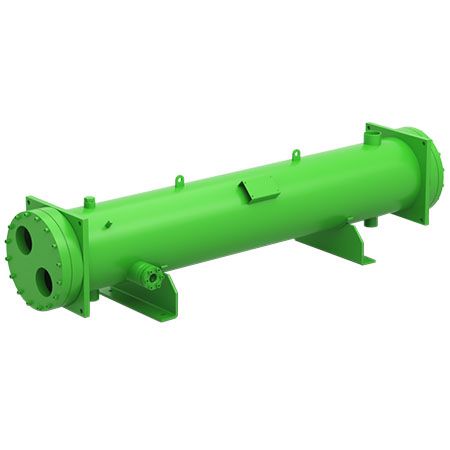

Evaporators

Evaporators are either shell and tube type or brazed stainless steel plate type and are designed for high heat transfer efficiency. Each refrigeration zone has its own independent evaporator, so failure of one refrigeration compressor will have no effect on the other circuits.

Controller

State of the art PLCs (programmable Logic Controller) are used for close monitoring of the inlet, outlet and dew-point temperatures of these dryers, Their modular and versatile features make them suitable for various application including local and remote display.

As an industry leader in compressed air-drying technology Next uses rotary screw compressors for all high-capacity dryers to provide extra reliability and more energy savings

Heat Exchangers

Next’s high thermal efficiency, ASME – stamped shell-tube type pre-cooler/ reheater and air to water/ glycol plate heat exchangers are designed for low pressure drop and maximum performance.

Demand-Activated, zero purge Condensate Drains

One of the important components of the dryer is the discharge of the condensate which has been removed from the compressed air supply. Next’s pneumatic zero purge drain system automatically discharges contaminated condensate from compressed air systems.