NFS Series (600-80,000 CFM)

Flanged Moisture Separator

The NFS series separators are an ideal solution for medium to large flow applications. Our range of Flanged Water Separators include connections ranging from 2″npt to 12″ flg. Stainless steel internal parts for maintenance-free operation and a side mounted drain port provides permanent drainage to an electronic drain or for a drain balance line.

Next’s series flange separators are designed to eliminate 99% of all entrained liquids and particles that are 10 microns and larger in size. The NFS – Series are fabricated from carbon or stainless steel and are manufactured in accordance with ASME CODE Section VIII, Division The NFS-CT series separators are fabricated from cast iron which meets ASTM-A-278 Class 35 standards are designed to meet ASME Code, Section VIII for unfired pressure vessels. The unique centrifugal action removes contaminants at low pressure drop from maximum energy savings.

By installing the Fabricated Flanged Water Separator, you will reduce the risk of contamination to production equipment, product spoilage, and costly shutdowns caused by damage from high levels of moisture and condensate in the system.

Note: While highly efficient, condensate separators will not remove the oil from the air stream, additional coalescing and particulate filters down stream may be required to remove fine traces of oil, water and particles.

NFS Series Features

- Fabricated separators offered in both horizontal and vertical configurations

- All fabricated separators are ASME coded

- At rated capacity, Pure Stream NFS separators remove 99% of the condensed moisture and maintain this effectively down to 20% of rated capacity

- Maximum efficiency with minimal pressure drops

- High pressure units available for up to 2,000 PSIG

- Stainless steel available on fabricated separators

- Special designs are available – consult CAG Purification

- Designed centrifuge and a high efficiency fixed impeller with “O” ring seal and anti-re-entrainment disc to ensure moisture free air downstream.

Max Operating Pressure

- 150 & 500 psig

- 10 & 34 Bar

Flow Rates

- 600 – 80,000 SCFM

Inlet /Outlet Connections

- 3” To 24” FLG

Operating Temp Range

- 450 & 650 °F

- 232 & 343 °C

Material

- Carbon Steel

Certified

- ASME Certified

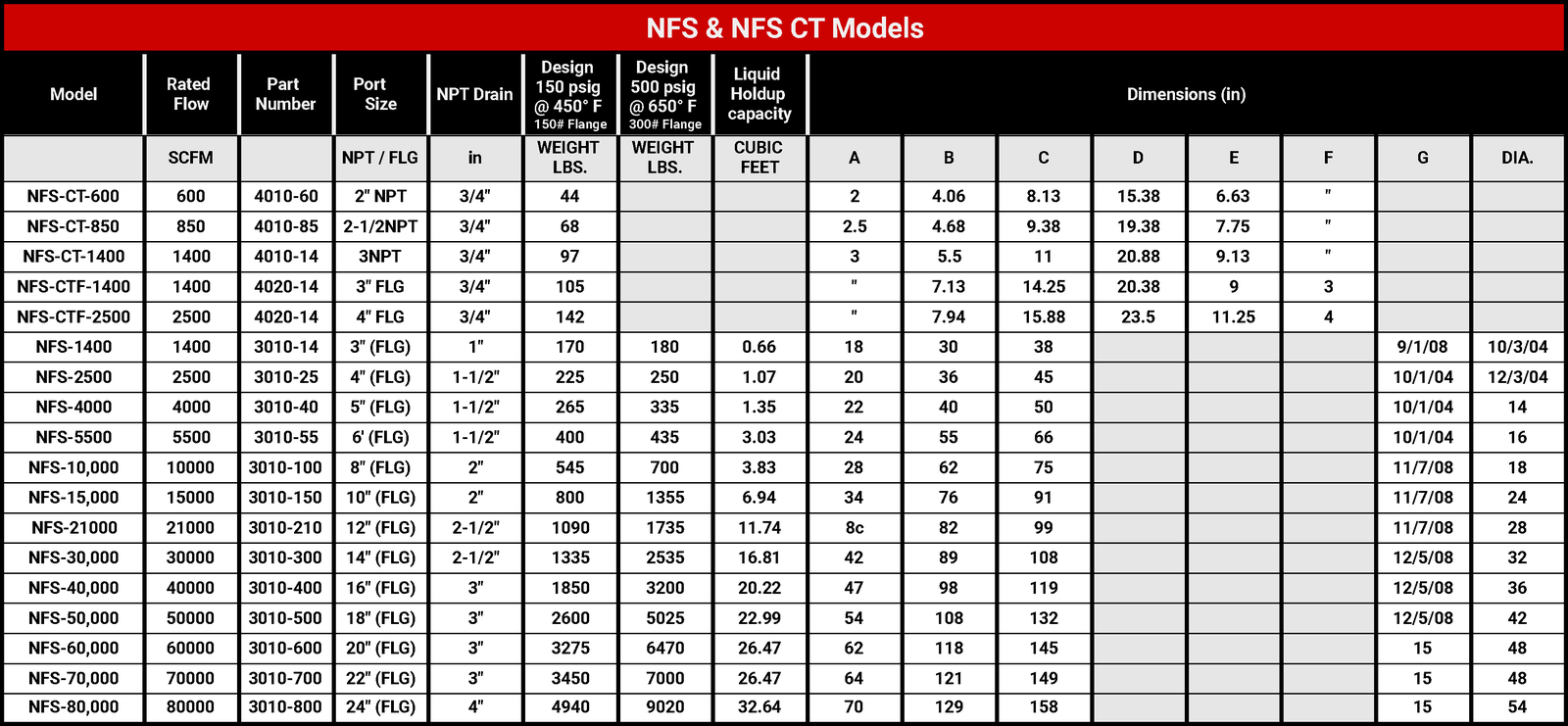

NFS & NFS-CT Series Range

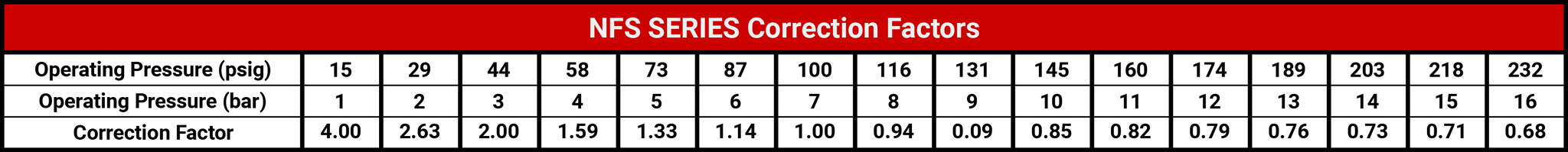

Correction Factors

For maximum flow rates, multiply model flow rate shown in the table above by the correction factor corresponding to the working pressure.

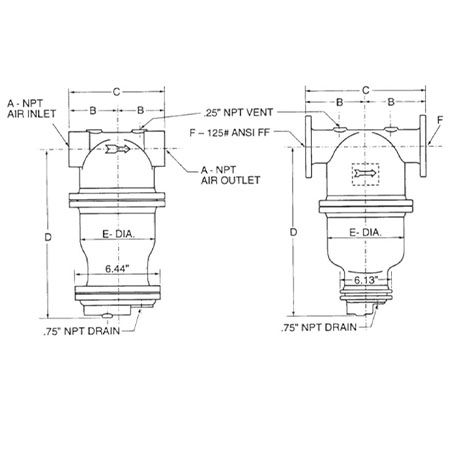

NFS-CT

NFS

NFS Series Options

The Next condensate drain series, drain without the loss of compressed air, guarantees a secure and economical drainage of condensate for any application.

The sizing of the condensate drains matches perfectly the volume flows and guarantees secure drainage even with higher condensate volumes.

Electronic Zero Loss Drain

NBM- Series

Timer Condensate Drain

NTD- Series

Mechanical Zero Loss Drain

NWH- Series

External Gravity Fed Zero Loss Float Drain

NEFD- Series

Your next step toward working with NEXT Air & Gas is to contact us for a Quote. Fill out the information below and give us the appropriate information needed to get started. Be sure to fill out all the contact information and our team will reach out with any questions or concerns.

If you’d rather speak to Sales Engineering, feel free to contact us at (865) 635-8178.

Below are links to product information and brochures. Please click and download at your convenience. If you have any questions or suggestions on materials you think would be helpful, please call us at (865) 635-8178.

Overview

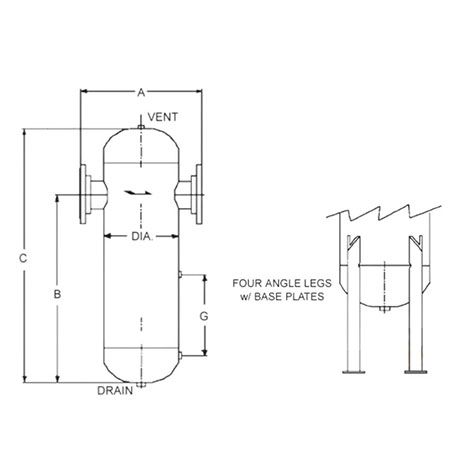

NFS Series

- Dished Head Above Nozzles

- Fabricated “L” Shaped internal vortex nozzle

- Vortex containment plate near bottom

- Fully welded body

NFS-CT Series

- Nozzles located near top of body

- Cast cone within

- Vortex contaminant plate near bottom

- Body Flange enables inspection

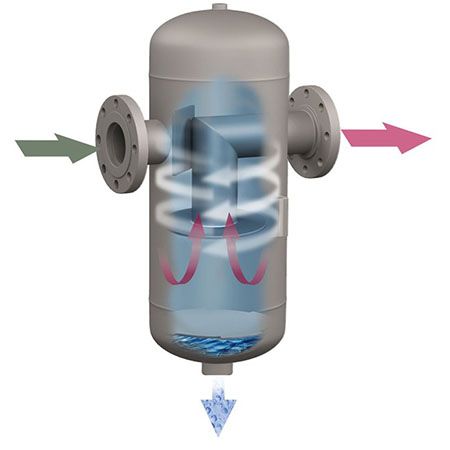

Principle of Operation

Gas, laden with moisture enters the inlet of the separator where a deflector plate directs the flow in a downward centrifugal motion. The entrained moisture is then separated out of the flow by a reduction in velocity. The separated liquid is sent to the outer walls of the separator and falls below the re-entrainment breaker plate where it is prevented from re-entering the flow stream. A dry, clean flow then results, exiting upward through the outlet separator.

Bulk water separation is a critical early step in the compressed air treatment process. Water separators remove large diameter water droplets from the air stream, enhancing the performance and durability of downstream treatment equipment such as coalescing filters and air dryers. Water separators are typically installed immediately downstream of coolers and wet receiver tanks.